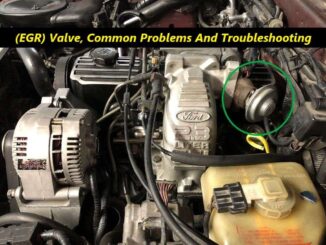

The exhaust gas recirculation (EGR) valve, does exactly what the name implies. It circulates, exhaust gas, for a second time.

So, exhaust gas recirculation (EGR) valves, do not normally require maintenance. But, they can become clogged with carbon deposits.

As a result, carbon deposits can cause the exhaust gas recirculation (EGR) valve to stick. Consequently, preventing it from opening or closing properly.

For example, an exhaust gas recirculation (EGR) valve, that’s stuck open. Will act like a vacuum leak and cause, a rough idle, stalling and even a no start.

And, an exhaust gas recirculation (EGR) valve, that has failed, and refuses to open. Will allow higher emissions, and may also cause detonation (spark knock).

Different Valve Types, That Do The Same Job:

- Ported (EGR) valves (1973 to 1980s).

- Positive back pressure (EGR) valves (1973 & up).

- Negative back pressure (EGR) valves (1973 & up).

- Pulse-width modulated electronic (EGR) valves (early 1980s & up).

- Digital electronic (EGR) valves (late 1980s to 1990s).

- Linear electronic (EGR) valves (early 1990s & up).

Exhaust Gas Recirculation (EGR) Valve, Failure Symptoms

Most (EGR) valve failures happen, because the valve itself gets, stuck open or closed. This is due to, a build up of soot, carbon deposits, and a sticky tar like substance. So, a faulty (EGR) valve, should cause, a check engine light to turn on. And, may even set a engine code. P0400 Through P0499 – Auxiliary Emissions Controls

This is to inform the driver, that something that affects the emissions system, is not working correctly. However, before getting to a total failure, the (EGR) valve will slowly degrade in operation.

As a result, causing it to react, slower to input and partially stick. And, if the valve is stuck closed, it would cause higher temperatures within the cylinder, theoretically leading to spark knock.

However, as most modern engines have knock sensors, and they’ll most likely adapt. So, it probably won’t feel all that different. Most likely it will stick open, when it should not. Causing, a rough idle, leading to a reduction in performance.

This degradation over time, will be slow, but should be noticeable. It will also mean, worse fuel economy. Carbon deposits build up rapidly, especially if most of your driving happens are, within the city and short trips. This driving pattern, doesn’t allow the engine to reach, operating temperature and run long enough, to remove harmful carbon deposits.

Exhaust Gas Recirculation (EGR) Valve, Cleaning

Depending on the (EGR) valve, it may be possible to extend its life, by cleaning it rather than replacing it. However, to do the job thoroughly, you’ll need to remove the valve to clean it. Consequently, this could end up taking more time, than replacing it with a new valve. But, if successful will obviously be, a cheaper fix.

Exhaust Gas Recirculation (EGR) Valve, Replacement

Most (DIY) mechanics, should be up to the task, of replacing an (EGR) valve. We’d recommend taking pictures of the engine bay and connections, to and from the (EGR) valve. Let the engine cool down, disconnect the battery and wait a few minutes for the electrical system, to discharge completely. Isolate the battery terminals as well, to prevent shorting. Finally, before removing anything, check that the replacement (EGR) valve you’ve bought, looks identical to the old one.

If the (EGR) valve has vacuum pipes leading to it, label them before twisting and pulling the pipes off. Then, carefully take off any electrical connections. This should be possible by hand, even if they are tight.

The valve itself, may be mounted within a sturdy outer body, bolted to the cylinder head. Because, it has hot exhaust gases going through all the time, the bolts holding it on, may be particularly tight.

So, it’s always a good idea, to spray these bolts with a lubricant, such as WD40. Consequently, this will help remove stuck bolts. Once the bolts are all off, take the valve and body out. Finally, remove any old gaskets.

Simply reverse the process above, with the new exhaust gas recirculation (EGR) valve, to fit it to the engine.

Conclusion

Find out what kind of exhaust gas recirculation (EGR) valve, you have, so you can use the appropriate test procedure. Examine the valve or refer to a service manual. Also, on some vehicles, you may find this information, on the under hood emissions decal. Then, find out what kind of vacuum controls, are used in the vacuum plumbing.

For instance, does it have a ported vacuum switch or a solenoid? To find out, follow the vacuum connections from the valve. Then, refer to a service manual or the under hood emissions decal, for vacuum hose routing information.

BY DANNY BENDER