So, your driving down the road and all of a sudden you hear, a engine knocking ticking noise.

Many assume this engine knocking ticking noise, is the end of their engine and just move on.

But, there are some ways to narrow down, where the engine knocking ticking noise, is actually coming from. And, how bad it really is.

So, internal mechanical problems, can cause a engine knocking ticking noise.

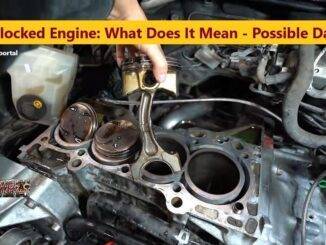

One such problem stems from, excessive clearance, inside the bearings in the connecting rods.

Consequently, they can transfer the downward movement of the pistons, to crankshaft rotation.

As a result, each time the piston changes direction, there is a noise from the metal hitting metal.

This is often referred to as, a rod knock. It is usually very rhythmic and it increases with, engine speed and intensifies, with engine load.

Diagnose Engine Knocking Ticking Noise, With A Timing Light

So, valve train noises occur, at half of crankshaft speed. But, even if your ear can’t tell, whether the noise is happening at 800 or 400 rpm, your eyes can.

Hook up the timing light, to any one cylinder and watch the flash. Look at the light for a while, to see if it coincides with the knock. If it does, it is valve train related.

But, if the noise seems twice as fast, it is probably in the:

- Crank

- Mains

- Rods

- Rod bearings

- Pistons

- Harmonic balancer

- Flexplate

Rod knocking noises, are loudest at higher speeds (over 2500 RPM). So, feathering the gas pedal, may result in a distinctive back rattle, between 2500 and 3500 RPMs.

If enough rod bearing material has been worn away, it may even, double knock. As a result, the piston will whack the cylinder head. In addition, to the big end of the connecting rod, banging on the crankshaft rod journal.

It will sound like a, hard metallic knock (rod) with an, alternating and somewhat muffled, aluminum (piston) knock sound. Wrist pin knock, in modern engines, is very rare today, but still possible. As a result, engine replacement, may be necessary.

Diagnose Engine Knocking Ticking Noise, With A Low Voltage Test Light

NOTE: This is old school and not safe. Short out the plug wires, one by one, with a common low voltage test light. Because, this may determine which cylinder, contains the noisy parts. Consequently, you won’t get the bulb to light up, but it is a easy way to short out the cylinders.

So, attach the alligator clip, to a ground, away from fuel system components. And, pierce the wire boots at the coil pack or distributor end of the wire.

You can also use straight pins, stuck in the ankle of the wire boots in the distributor. Then you touch, a grounded jumper wire to each one.

Noise Changes

If the noise changes, when the plug wire is shorted to ground. Then, you can figure that the problem, is in the reciprocating bottom end parts. Possibly piston, wrist pin, connecting rod or connecting rod bearing. So, the reason the sound changes is, that when you short the cylinder plug wire. Then, you are stopping the combustion chamber explosions, that are slamming the piston downward. Because, that makes the inside of the big end of the connecting rod, bang against it’s connecting rod journal.

If you get a change in the sound, when you short a cylinder out. Then, you have confirmed that, the head and or oil pan must be removed, to actually find the problem. So, replacing a crankshaft, is always risky. Because, whatever made the bottom end fail, has also contaminated the rest of the engine, with debris. Causing, engine knocking ticking noise.

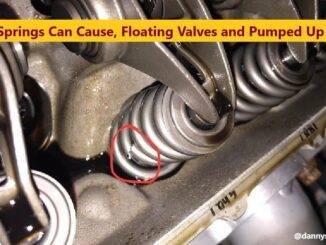

Valve Train Noises

Valve train noises, generally are loudest, up to 1500 rpms. But, Lifter noise is commonly misdiagnosed. In reality, lifters are quite trouble free.

So, dirt contamination on a engine, full of sludge is the number one cause of, true lifter noises. Consequently, low oil pressure, is number two. Whatever you do, don’t put engine flush, in a sludged engine!

We call it “Instant rod knock” ,because of the way it overloads the oil filter, to the point of opening the filter bypass valve, flooding and destroying the engine bearings with debris.

So, the only safe way, to clean a engine full of sludge is to, speed up the oil changes. Therefore, letting the detergent in the oil do the cleaning, at a controlled rate. Like every 500 miles.

Replacing The Oil Pump Only, Is A Common Mistake

Over 95% of replaced oil pumps, did not need to be changed and rarely wear out. If you have low oil pressure, I would be more concerned about, excessive clearances and worn parts.

A deep rapping noise from the engine, is usually rod knock. This is brought on by, extreme bearing wear or damage.

Sooner or later one of the bearings will fail, and when it does, one of two things will happen. The bearing will seize and lock up the engine, or it will attempt to seize and break a rod. Consequently, bearing noise is not unusual, in high mileage engines.

Bearing noise, can also be caused by:

- Low oil pressure

- Using too light a viscosity oil

- Oil breakdown

- Dirty oil or dirt in the crankcase

- Excessive blow, by from worn rings and/or cylinders (gasoline dilutes and thins the oil).

- Incorrect engine assembly (bearings too loose), loose or broken connecting rod bolts, or abusive driving.

Bearing wear can be checked by, dropping the oil pan and inspecting the rod and main bearings.

If the bearings are badly worn, damaged or loose, replacing the bearings may buy you some time. But, if the bearings are badly worn or damaged, the crankshaft will probably have to be reground.

Other mechanical problems that lead to, Engine Knocking Ticking Noise are:

- Defective main crankshaft bearings.

- A cracked or broken flywheel or flexplate, that attaches the engine to the transmission.

- A worn water pump bearing.

- A failed or loose timing belt tensioner can knock, when the timing belt slaps against it.

- An air conditioning compressor can knock, when it is failing or icing up.

- An alternator with worn rotor bearings, can knock when the pistons fire.

Also, don’t forget about Spark Knock. So, Spark knock, aka detonation, is when spontaneous combustion occurs at multiple flame fronts simultaneously inside a combustion chamber.

Detonation occurs because, the fuel is subjected either to too much pressure, too much heat or both. Also, by using a mechanics stethoscope, little noises become big, making them easier to find.

In Summary: Engine Knocking Ticking Noise

So, a heavier knocking sound, that gets louder, as engine (RPM)s pick up. Usually, points to a rod knock or main bearing knock. Also, the pistons’ connecting rods, utilize bearings at their connections to the crankshaft. So, in the event of extreme wear or low oil levels, these bearings can develop, “slap”. And, wear to a point where they loosen up at the crankshaft.

The main bearings for the crankshaft, can also develop the same problem. And, it’s a problem that won’t get better on its own. Finally, that engine knocking ticking noise is going to escalate, to a point where, there’s only one recourse. And, that might be, a complete engine rebuild.

Thank You !!