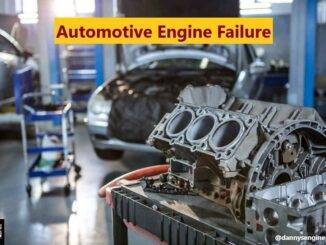

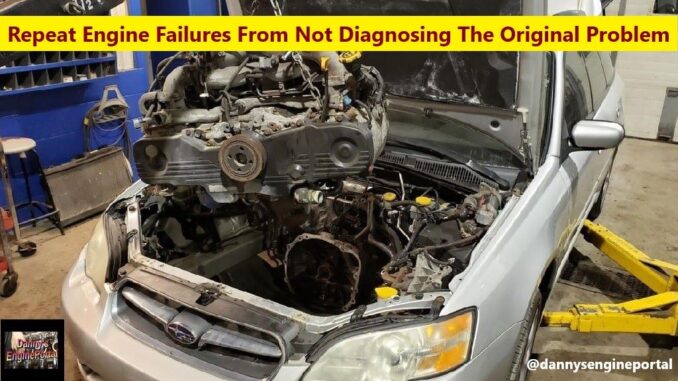

The installer’s worst nightmare, repeat engine failures from not diagnosing the original problem.

So, you have replaced an engine, cylinder head, or crankshaft in your car. But a short time later you have a repeat failure of the same part.

As a result, not finding the original problem can cost you a ton of money and time down the road.

Repeat engine failures often occur because the original underlying cause of the initial problem was never correctly diagnosed. That’s why fixing only the symptoms allows the true problem to persist.

And, inevitably causes the new part to fail in the same way. Another common mistake in diagnostics is falsely condemning a part that is really just out of adjustment.

What Are The Causes

1. Fixing The Damage, Not The Cause

Replacing a blown head gasket without identifying and fixing the overheating issue. (faulty water pump, clogged rad, or leak) means the new gasket will also fail.

2. Not Fixing The Root Cause Of Lubrication Problems

An engine fails due to oil starvation. Just installing a new engine will not fix the root cause of the problem. As a result, you will have repeat engine failures.

3. Failing To Flush Contaminants

A catastrophic failure can create metallic debris and other contaminants that circulate throughout the system. If the related systems are not thoroughly cleaned or replaced, the debris can damage the new engine. Engine bearings are usually the first to fail. As a result, you will have repeat engine failures.

4. Incorrect Installation Or Incompatible Parts

Never use an incompatible replacement engine, wrong parts or make installation errors. Because, this will put immediate undue stress on the system. As a result, you will have repeat engine failures.

5. Neglecting Supporting Systems

Problems in related systems, such as a faulty fuel injector or a weak ignition system leading to misfires. Also, affecting idle quality. This can place excessive stress on internal engine parts. It can cause them to break down repeatedly if the original fault is ignored.

What Are The Consequences

1. Significant Financial Loss

So, repeat engine failures or replacements are costly. It is a burden that is often avoidable with a complete initial diagnosis.

2. Extended Downtime

The car is out of commission multiple times leading to inconvenience and potential additional costs for alternative transportation. All because of repeat engine failures.

3. Safety Hazards

So, an engine failure can occur at any time. Including while driving, which poses a serious safety risk.

4. Accelerated Wear And Tear

Undiagnosed minor issues force the engine to work harder. As a result, accelerating wear and tear on all parts until another major failure occurs.

What To Do To Prevent These Failures

The key to help prevent repeat engine failures is a comprehensive diagnostic process. One that identifies the original underlying cause of the failure, rather than just fixing the resulting damage.

1. This Involves, Thorough Inspection

Beyond the immediate site of damage, a full inspection of all related systems (cooling, lubrication, fuel, electrical) is crucial.

2. Professional Expertise

Relying on qualified technicians who follow correct diagnostic procedures is essential.

3. Quality Parts

Using high quality, compatible replacement parts.

4. Scheduled Maintenance

Always following the car makers suggested maintenance schedule. As it helps identify and resolve minor issues before they escalate.

Always Start With Searching For The Original Problem

(ECU)s and sensors control, almost all of today’s cars. And, any one of them failing can cause repeat engine failures.

So, the engine, piston, or cylinder head is replaced. But, shortly after the customer returns with the same or a new problem. Because finding and fixing the original problem never did happen. Quite often it’s a leaking or blown head gasket.

So, before replacing any of these parts, you must first find the original problem that caused the original failure.

How To Avoid Repeat Engine Failures

1. Verify The Problem

Before one minute of time is spent on diagnosis, be certain that a problem actually exists. Because, if the problem does not exist it cannot be solved or tested to verify that the fix was done.

2. Perform A Visual Inspection And Basic Tests

So, a visual inspection is the most important part of a diagnosis. Most experts agree that most engine problems can be found, simply by performing a visual inspection.

3. Retrieve The (DTC)

If a (DTC) is present in the (ECU)s memory, it should turn on a warning light. Either a (CEL) or a (SES) light.

4. Check For (TSB’s)

Check for corrections in bulletins, that match the symptoms. NOTE: (DTC)s must be known, before searching for service bulletins. Bulletins often include info on solving problems that involve a stored (DTC). And, some can cause repeat engine failures.

5. Look At Scan Tool Data

The best way to look at scan data, is in a sequence. Because, that can tell you the most about the operation of the engine.

6. Narrow The Problem Down, To A System Or Cylinder

Consequently, narrowing the focus down to a system or individual cylinder is the hardest part of the entire diagnostic process.

7. Determine The Root Cause And Fix The Problem

Always follow the car maker’s suggestions when you fix or replace any part. And, their suggested procedures and methods.

8. Verify The Fix, And Clear Any Stored (DTC)

(ECU)s and sensors control most of today’s cars. So, there may be as many as 20 sensors, feeding info to the cars (ECU). And, there are also other sensors, while not directly attached to the (ECU), that do affect the info as well.

Furthermore, these sensors are part of other systems that allow the car to operate correctly. So, all of these systems must be in correct operating order for the engine to function correctly. As a result, you risk repeat engine failures.

Some Of The Systems That Play An Important Role, In The Correct Running Of Today’s Engines Are:

- Exhaust

- Cooling

- Ignition

- Oil

- Fuel

- (EGR)

- (IAT)

- (MAF)

- (ECT)

- (PCV)

- (EVAP)

These systems are all controlled by the (ECU). And, the (ECU) gets all its info from all the sensors. So, the end result of this info is a good or bad running engine.

Consequently, failure of any of the sensors, or failure of the system itself, can cause an engine failure. So, just as with the original engine, it is reasonable to expect the same mileage from a rebuilt engine. And now you have to add labor and any additional parts as well.

In Summary: Repeat Engine Failures

So, there are sensors that provide info to the (ECU) that allows the engine to run correctly. But, these parts also have 100,000 miles on them. So, always remember that the same mileage applies to other parts as well.

Then, if you have not found the original problem, keep searching. Otherwise, you could end up with the installer’s worst nightmare. “Repeat Engine Failures”.

Thank You!