The main function, of automotive engine valves, is to let air in and out of the cylinders.

Above all, the valves in your cylinder head, are a vital part of your engine and undergo, enormous stresses.

So, the automotive engine valves, that let the air into the cylinder, are the intake valves. However, the automotive engine valves, that let the gases escape, are the exhaust valves.

To clarify, automotive engine valves, are designed to open and close, at precise moments.

Overhead Valve (OHV), Overhead Camshaft (OHC)

The Overhead Valve Engine (OHV), operates by using pushrods.

The Overhead Camshaft Engine (OHC), operates, directly on bucket tappets. As a result, it needs fewer parts, to operate the valves.

This is why, automotive engine valves, play a pretty critical role, in an engines performance. So, the more air you can move in and out of the engine, the more efficient it will be.

So, intake valves handle cool, low pressure, low density gases. However, exhaust valves handle hot, high pressure, high density gases.

Damaged Automotive Engine Valves, Can Result In:

- Reduced Engine Power

- Poor Gas Mileage

- Complete Engine Failure

Automotive Engine Valves, How They Can Fail

Any valve will eventually wear out, if driven enough miles. But, many valves call it quits, long before they should. Usually, because of burning or bending:

Burnt Valves

Exhaust valves, are the ones most likely to burn. Because, they run, hotter than the intakes. Most often, caused by combustion gases, leaking between the valve and the valve seat. First, the hot combustion gases, are forced past the valve. After that, the heat starts to burn away, the edge of the valve.

So, a burnt valve, will cause issues, with your vehicle’s performance and fuel mileage. Consequently, rough idle, reduced power, backfiring and engine misfire, are all symptoms of burnt valves. Incoming air and fuel, cool the intake valves. And, that’s why they operate, at a much cooler temperature.

Bent Valves

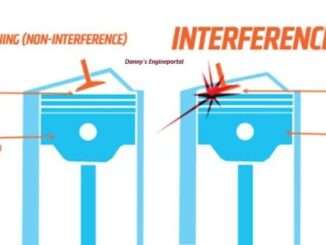

The most common failure of valves, is bending or breaking. Most often, from contact with the pistons. The valves contacting the top of a piston, is due to wrong engine timing. And, can be caused by, a broken or damaged timing chain or belt. If you suspect your engine may have, bent valves, it is crucial, not to attempt to start the engine.

The bent valves above, are a result of a timing belt, that has broken. Your timing belt doesn’t last forever and needs to be replaced, according to the manufacturer’s specs. Replacing your timing belt is cheap insurance, against costly engine damage. Also, sticking valves from carbon buildup, can do the same thing.

How Are Automotive Engine Valves Cooled

So, the intake and exhaust valves, rely on physical contact with the valve seat and guide, for cooling. Because, the combustion heat is conducted away, through the valve seat and guides.

So, good valve seat contact, is essential, to prevent burning. Because, if the valve does not receive adequate cooling, it can overheat, burn and fail.

Testing Valves For Leaks

Leaking, Automotive Engine Valves

Doing a cylinder leakdown test, is an excellent way to find out, where problems are, without tearing down the engine. Listening for where the air is leaking by ear, can isolate the problem. Cylinder Leak Down, Test Results.

Intake Valve Leaks

Air heard whistling out of the intake, carburetor or throttle body, means an intake valve is leaking.

Exhaust Valve Leaks

Air heard hissing out of the exhaust pipe, turbocharger or exhaust manifold, means an exhaust valve is leaking.

How Many Automotive Engine Valves Can You Have

A multi-valve engine design can have, three, four or even five valves per cylinder. Above all, to achieve the best engine performance.

Three Valve, Head

So, this has a single large exhaust valve and two, smaller intake valves. A “three valve” layout, allows better breathing, than a “two valve” head. Consequently, the large exhaust valve, results in an (RPM) limit, no higher, than a “two valve: head.

Four Valve, Head

So, this is the most common type of “multi valve” head. It comes with, two exhaust valves and two similar (or slightly larger) inlet valves. This design allows similar breathing as compared to, a ‘three valve” head. The small exhaust valves, allow high (RPM). As a result, this design is very fitting, for high power outputs.

Five Valve, Head

Finally, less common is the “five valve” head, with two exhaust valves and three inlet valves. All five valves, are similar in size. This design allows for, excellent breathing. And, as every valve is small, high (RPM) and very high power outputs, are theoretically available. Although, compared to a “four valve” engine, a “five valve” design, should have a higher maximum (RPM). So, as you can see, automotive engine valves, come in many configurations.

Conclusion

So, valve problems, are one thing you should not ignore. Today, getting a valve job may save your entire engine. Because, most of the engine parts are now located, in the cylinder head. However, they are easy to prevent or at least delay, with proper engine maintenance. So, have your oil changed regularly. And, fix any other engine problems, ASAP.

BY DANNY BENDER