(VVT) Variable Valve Timing, is a 2-stage, hydraulically controlled cam phasing system.

So, as engine technologies improve and become less expensive, (VVT) variable valve timing, continues to improve performance and economy.

Car makers have now adopted, various (VVT) variable valve timing design approaches, and technologies. Most importantly, to control the valve timing, and how long the intake and exhaust valves remain open.

So, the (VVT) variable valve timing system, uses engine oil pressure, to change the position of the intake camshaft. As a result, optimizing intake valve timing for operating conditions. Note: Only the intake is involved.

Also, depending on the engine’s needs, the system may rotate the camshaft, in the advanced or retarding direction. Adjustments in the overlap time, between the exhaust valve closing and intake valve opening, results in improved engine efficiency.

(VVT) Variable Valve Timing technology, controls three key characteristics, of the intake and exhaust valves:

- Valve timing – The points in the piston’s movement, at which the valves open and close.

- Duration – How long the valves, stay open.

- Valve lift – How much the valves physically open, (their opening aperture).

To do this, various sensors, such as (MAF) and (CMP) sensors, feed information to the car’s (ECU). Finally, using various mechanisms, to control the aforementioned valve characteristics.

So, How Does (VVT) Variable Valve Timing Work

(VVT), alters the timing of valve lifting, to improve performance and economy, in specific driving situations.

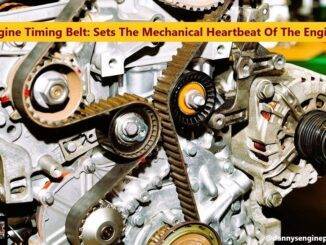

Visualize this as a hollow, enclosed gear inside, where two star-shaped gears are placed, one inside the other. The outer gear, is the camshaft gear’s connection, to the belt or chain that drives it. The inner gear, connects to the camshaft itself. Normally, the two are meshed together, cog against cog, and turn at the same rate.

So, when oil pressure is introduced, the gears can be separated. Consequently, changing their speeds, relative to one another momentarily. Finally, this increases or decreases, the speed of the camshaft, in relation to the engine’s drive timing. Also, that, in turn, changes the duration of the valve lifting, to control intake and exhaust.

(VVT) Variable Valve Timing Basically Comes In Two Types:

- Single (VVT) Continuously varies the timing, of the intake camshaft.

- Dual (VVT) Continuously varies the timing, of the intake and exhaust camshaft.

So, the dual (VVT) system, helps the engine breathe more efficiently. And, is done by continuously adjusting the timing of the intake and exhaust valves. Because, this helps improve power, fuel efficiency and exhaust emissions.

Furthermore, Dual (VVT) Helps To Provide:

- Greater fuel economy, at all engine speeds.

- Greater low-speed torque, with less chance of power-robbing engine “knock”.

- Superior horsepower at higher engine speeds, without excess noise and vibration.

- Reduced emissions, at all engine speeds.

Also, dual (VVT) helps the engine give you the power and the fuel efficiency that you want. All while maintaining optimum emissions quality.

So, What Is The Difference Between, Single And Duel (VVT)

- Single (VVT) technology, adjusts the timing of, the intake valves only.

- Dual (VVT), adjusts both intake and exhaust valves (double-acting).

In both cases, the camshaft has two profiles for the intake valves:

- The economy profile, (below 6,000 rpm).

- The performance profile, (above 6,000rpm).

Consequently, when the (VVT) “kicks in”, oil pressure is exerted on an actuator. And, that shifts the camshaft slightly, engaging the “performance” setting.

So, with dual (VVT), the same thing happens. But, the difference this time is, the exhaust valves are activated. Now, the camshaft has two profiles each, for both intake and exhaust. Dual (VVT) also, minimizes the start/stop compression pressures, by adjusting the overlap sequences, between intake and exhaust valves.

The ability to simultaneously open, both intake and exhaust valves, also allows for maximum scavenging of intra-cylinder charge. Allowing very high (RPM) and tremendous amounts of power, from the same engine, that boasts impressive low-end torque.

Advantages Had With (VVT) Variable Valve Timing Include:

- Improved performance and economy at the same time.

- Faster catalytic converter heating, through improved exhaust control.

- Improved efficiency, over a wide range of engine operating speeds.

- Improved, engine timing.

Common Engine Error Codes

Two common engine codes are, P0011 and P0021 (CMP) “Bank 1” and (CMP) “Bank 2,” respectively.

Some Of The Common Areas To Look For Problems Are:

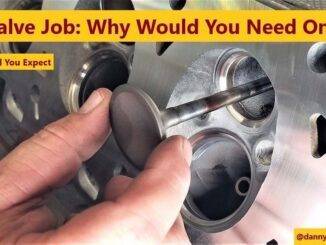

- Valve timing

- Oil control valve

- Oil control valve filter screen

- Camshaft timing/gears

- Electrical connectors and wires

- (PCM) or (ECM)

Consequently, dirty oil, can lead to sludge buildup, which can clog oil passages in the cam, resulting in cam failure. So, lack of regular maintenance, is a big problem with (VVT) systems.

Oil Changes Are Now More Important Than Ever Before

Most importantly, the (VVT) solenoid, needs clean engine oil, to work properly. So, what happens when, the engine oil becomes clogged with debris, dirt or other foreign particles ? It tends to clog up the passageway, from the solenoid to the (VVT) chain and gear.

Therefore, lack of regular oil changes, could damage the (VVT) solenoid, the (VVT) chain and the gear drive. So, to avoid this situation, make sure to have your engine oil changed, as recommended by the vehicle maker. Low oil levels, can also cause problems, with the (VVT) solenoid and other timing system components.

With (VVT) Variable Valve Timing (You No Longer Have An (EGR) Valve)

So, (VVT) systems have made (EGR) valves obsolete. (EGR) valves put smog causing nitrous oxides, back into the intake manifold. Consequently, the (VVT) system controls the timing, to leave inert gas in the chamber, for the next combustion cycle. Furthermore, controlling the combustion temperature and the production of nitrous oxides.

Conclusion

So, most (VVT) systems and its components, depend on the constant circulation of engine oil. Consequently, if there’s any problem with the oil flow, many parts can fail permanently.

BY DANNY BENDER