The last thing anyone ever wants to hear are the words “you have a head gasket leak”.

So, your vehicle has started overheating, but you cannot find the source.

Engine overheating is often the first sign of trouble, when you have a head gasket leak. If the gasket loses its ability to seal the head to the block, coolant can leak past the gasket.

So, a head gasket leak can be classified as either, an external or internal leak.

First of all, an internal leak, can be worse than an external leak. Both require the same amount of work to fix, but internal leaks can be far worse. First, a head gasket is a simple seal between the surfaces of the engine block, and the cylinder head(s).

The Head Gasket Has Two Primary Purposes:

- Sealing the combustion chamber. Firstly, the head gasket helps contain the combustion process, so you can have a properly running engine.

- Secondly, the head gasket provides a physical extension of the fluid passages, from the head to the block. So, fuel, oil, and coolant, all serve a different purpose and need to stay separated. Subsequently, while operating, in very close quarters.

The Head Gasket Has The Most Important Job In The Engine

Apart from sealing the cylinder, the head gasket also seals coolant and oil conduits, between the head and block. Because, any connectivity between them, will cause engine failure. White exhaust smoke, is an indicator of coolant burning. Also, another sign of a head gasket leak.

Being this close to the combustion process, the head gasket has to be tough. Despite the critical importance of this part, new head gasket sets, are surprisingly affordable.

Symptoms Of A Head Gasket Leak

Here Are The Most Common Symptoms, That You Have A Head Gasket Leak:

- An external oil or coolant leak at the seam, between the engine block and cylinder head. Consequently, is a sign that you have, a head gasket failure. On disassembly, check for cracks and cylinder head warping.

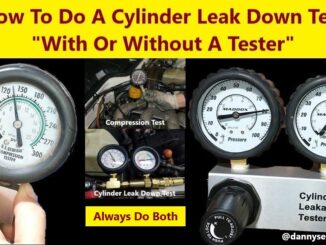

- Cylinder misfire is another sign, of head gasket failure. Especially if the breach is between, two cylinders on the same head. Cylinder compression and leakdown tests, can localize the leak for scrutiny on disassembly.

- Misfire on startup, if accompanied by a puff of white exhaust smoke, could indicate a leak. Usually, from the cooling system, into the cylinder.

- Overheating is one of the less-obvious signs, of a blown head gasket. Depending on the severity of the leak, you may see, bubbles in the coolant recovery tank.

- Discolored fluids are more subtle signs, of a blown head gasket.

- Coolant-contaminated oil, takes on a frothy consistency. It’s like finding a latte under your oil cap, or in the valve covers.

- Oil-contaminated coolant, forms a mayonnaise-like film. And, you might find it, on the radiator cap, oil filler cap or in the coolant recovery tank.

If You Suspect You Have A Head Gasket Leak, Take Your Time Diagnosing The Problem:

- Dry and wet compression tests and a cylinder leak down test, might reveal the location of the leak.

- A block tester can help determine, whether combustion gases are present, in the cooling system.

Head Gasket Leak Prevention

Sorry to say, but there is no fool proof way, to prevent a head gasket leak. Head gaskets do wear out over time. And, there are many engines out there, that are just prone to leaks, because of their design. Despite your best efforts, the gasket may fail anyway.

So, the best way to slow down a head gasket leak, is to ensure your engine does not overheat.

Check the radiator and coolant recovery tank, anytime you check your oil level. Add coolant as needed, and watch out for any unexplained fluid loss. Check the radiator hoses for splits or frays and replace, at the first sign of damage.

Watch for fluid leaks under your vehicle, and any unusual smoke. Signs of a head gasket leak, will vary by the engine and the particular way the gasket failed.

One Very Important Note !!

A cylinder head may have to be removed, for any number of reasons. For instance, a head gasket leak or even a valve job. Most importantly, make sure you take it to a reputable machine shop, and make sure that the head is resurfaced. Even if the head is not warped, it should be resurfaced. Because, the head must have the proper (RMS) finish, for the new head gasket to seal properly. As a result, if you don’t, you are asking for a second failure.

Conclusion

One of the best ways to diagnose this problem, is to use a combustion leak tester. Basically, this is a device that, detects exhaust gases in the coolant.

So, when dealing with a head gasket failure, it is important to identify the root cause of the failure. Before, installing a new gasket. Otherwise, you risk the chance of a second failure, and destroying the new gasket.

BY DANNY BENDER