What is engine misfiring and what are the main causes.

Engine misfiring is bad, so it’s best to find the problem and fix it as soon as possible.

Because, engine misfiring reduces gas mileage and increase emissions, which can cause you to fail an emissions test.

More seriously, engine misfiring can cause damage to other engine parts, like the (O2) Sensors or catalytic converters.

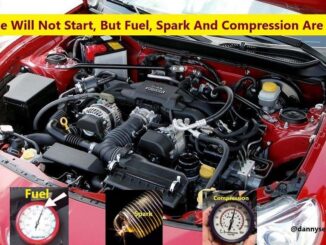

Engine Misfiring Occurs When, One Or More Of These Factors Is Wrong, Missing Or Just Not Working Together:

- A too lean or too rich air fuel ratio.

- Bad ignition spark / wrong timing of the ignition spark.

- Low compression / air fuel ratio is leaking out.

- The timing of the inlet/outlet of the air fuel ratio is wrong.

Common Misfiring Causes

If one or more of the above factors aren’t in proper working condition, you’ll run the risk of engine misfiring. There are a variety of different misfire causes that can occur. And, most of them, will keep a cylinder from combusting properly. Sometimes it takes a combination of issues, in order to make a cylinder misfire. Other times, misfiring isn’t consistent, and sometimes the cylinder will fire properly. So, it all depends on the type of issue, and how severe the issue is.

Faulty Or Fouled Spark Plugs

Spark plugs provide the spark for the ignition of the, air fuel mixture in the combustion chamber. But, spark plugs can go bad for a number of reasons, and are one of the leading causes of misfiring. Spark plugs can get fouled from oil leaking into the combustion chamber, or from carbon buildup.

They can also wear down more quickly, from overheating and improper plug gap. The bottom line is, that if you’re experiencing misfiring one of the leading causes, is bad spark plugs. It’s easy to check and easy to fix.

Cracked Distributor Cap ( If You Have One )

The distributor is what controls, the timing of the spark. When the distributor is functioning properly, the spark to each spark plug is sent, at just the right time. And, will ignite the air fuel mixture, right when the piston is ready. A cracked or damaged distributor cap, can cause the signal to be lost. As a result, causing one or more of the spark plugs, to misfire.

Lean Air Fuel Mixture

The air fuel ratio is a pretty delicate balance. If the mixture gets out of balance, it can cause a misfire. So, what are some ways that the, air fuel ratio can get out of balance? If things like the fuel pump or the fuel injectors get clogged. Then, not enough fuel will be able to get to the combustion chamber, and can readily cause a misfire.

Lack Of Compression, From Leaking Valves Or Head Gasket

If a cylinder lacks proper compression, then the spark from the spark plug, won’t ignite the air fuel mixture. Most of the time, by leaky exhaust valves or a blown head gasket. In either case, you’ve got a pretty major problem. So, there is a way to tell whether your head gasket, or a leaky valve is causing the problem. Check to see if two cylinders, next to each other are misfiring.

If so, then you most likely are dealing with, a blown head gasket, instead of a leaky valve. In addition, if an engine overheats or runs hot and if you’re noticing that you’re also, mysteriously losing coolant. Then, you most likely are dealing with, a blown head gasket.

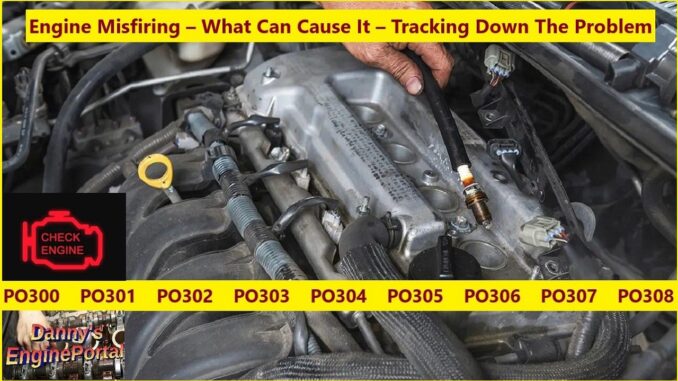

Quick Diagnosis With A Engine Misfiring Code

On OBD-II vehicles, the OBD-II system will not only identify misfires, but also coil and injector problems.

Consequently, if the (MIL) is on, you find a code for a misfiring cylinder. And, a second code, indicating an injector fault, for the same cylinder. Bingo, the engine probably has, a bad fuel injector.

Likewise, if you find a misfire code for a cylinder. And, also a code indicating a coil fault for a multi-coil, (DIS) or (COP) ignition. Then, you can probably bet, on a bad ignition coil.

In cases where there’s a cylinder misfire code, but no other codes. The ignition or fuel delivery system, may be borderline. But, not yet bad enough, to set a code of its own. A shorted or open fuel injector solenoid, or a shorted or open coil will usually set a code. Consequently, a dirty or weak fuel injector or a weak coil, probably won’t set a code.

Bad spark plug wires, are a common cause of misfire codes. So, after 50,000 or so miles, the (OEM) wires may be leaking current to ground. Sometimes, it can be, other wires shorting the spark, before it can reach the plug. Check resistance and if it exceeds specs, replace the wire set.

A Code ( P0300 – P0312 ) May Mean, That One Or More Of The Following Has Happened:

- Bad, spark plugs or wires

- Faulty, coil (pack)

- Failed, (O2) Sensor(s)

- Faulty, fuel injector(s)

- Burned, exhaust valve

- Faulty, catalytic converter(s)

- Stuck, blocked or leaking (EGR) Valve or passages

- Faulty, (CMP) Sensor

- Defective computer

Finding The Engine Misfiring Cylinder

In the case of a steady misfire, isolating the misfiring cylinder, is the first step in diagnosing the problem. The old fashioned method, for finding a weak cylinder was, to temporarily disconnect each of the spark plug wires. Just, one at a time, while the engine is idling.

When there’s no change in the idle speed, then you have pinpointed the weak cylinder.

So, a power balance test, will tell you the same thing. But, this requires some hookups and an engine analyzer. Most often, a power balance test is preferable, to pulling plug wires. Because, it keeps you away from the voltage. And, prevents the voltage from causing any damage, to the electronics in the ignition system.

When a wire is disconnected from a spark plug, the high voltage cannot follow its normal path to ground. As a result, this causes the voltage to, pass back through the coil. Most Ignition Systems, are robust enough to withstand such voltage backups intermittently, but not on a prolonged basis. If the coil or ignition module is already weak, it may push the component over the brink, causing failure.

Compression And Ignition Related Engine Misfiring

If you have a misfire and have isolated it to one cylinder, the cause can be obvious. Usually, when you remove the spark plug. If the plug’s insulator is cracked or broken, you’ve found the problem. When the plug appears to be OK, but is wet, inspect the plug wire and boots for damage. Measure the plug wire’s resistance, end to end, with an ohmmeter.

Refer to the vehicle manufacturer’s specs. But, as a rule, resistance should not exceed, 8,000 ohms per foot. Replace the wire if resistance exceeds specs. Finally, you have found the source of the misfire, if the plug is fouled. But, you still have to determine, what caused the plug to foul.

Heavy black oily carbon deposits, would tell you that the engine is burning oil. Worn valve guide seals and/or guides could be the problem. Also, worn rings and cylinders, can also allow oil to enter the combustion chamber. These are known as, mechanical engine misfires. Replacing the spark plug, will temporarily cure your misfire problem.

Now you can do a Cylinder Leakdown Test or compression test. Because, it will help you determine if the oil, is getting past the valve guides or the rings.

After testing, the cylinder shows little leak down, and holds good compression. Then, it is telling you that the engine needs, new valve guide seals and/or guide work.

A spark plug that shows heavy whitish to brown deposits, may indicate a coolant leak. It could be past the head gasket or through a crack, in the combustion chamber. Coolant makes a lousy lubricant and can cause ring, cylinder and bearing damage.

Loss of coolant can also lead to overheating, which may result in cracking or warping of aluminum cylinder heads. If you suspect this kind of problem, pressure test the cooling system to check for, internal coolant leakage.

Spark plugs that show pre ignition or detonation damage, may indicate a need to check engine timing. And, the operation of the cooling system and conditions, that cause a lean air fuel ratio. You might also want to switch, to a colder heat range plug.

Short trip, stop and go driving can cause, a rapid buildup of normal deposits on plugs. The cure here might be to switch to a one step hotter spark plug.

If the plugs and wires are OK, but the cylinder is weak, do a cylinder leakdown or compression test. You may find out, there is a compression problem.

The exhaust valves are the ones most likely, to lose their seal and leak compression. So, if you find unusually low compression, follow up with a wet compression test. Because, it can help you determine if the problem lies with, the valves or rings.

No change in compression with a wet test would tell you, the problem is valve related. A blown head gasket, may be another cause. But, if the compression readings are significantly higher, with a wet compression test. It is telling you, the piston rings and/or cylinder walls are worn.

Either way, your looking at major repairs. The only cure for a leaky valve, is a valve job. The only cure for a leaky head gasket, is to replace the gasket. Likewise, the only cure for worn rings and cylinders is, to overhaul or replace the engine.

A rounded cam lobe, may also cause low compression. If the valve doesn’t open, the cylinder can’t breathe normally and compression will be low. A visual inspection of the valvetrain, and cam will be necessary, if you suspect this kind of problem.

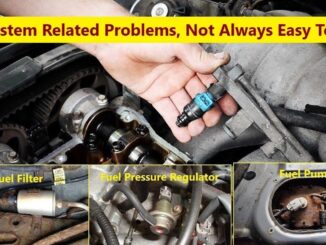

Fuel Related Engine Misfiring

If the ignition components and compression in a misfiring cylinder are fine. Then, that leaves a fuel related problem, as the only other possibility. You can start by checking for voltage, at the injector. A good injector should also buzz, while the engine is running. No buzzing would tell you, the injector is dead. While, a no voltage reading, would tell you it isn’t the injectors fault. Instead, a wiring or computer driver problem.

If the injector is buzzing and spraying fuel, but the cylinder isn’t getting enough fuel. Then, the injector is, dirty or clogged.

On car cleaning may help remove the varnish deposits, that are restricting the injector and fuel delivery. Finally, replace the injector, if it causes a steady misfire.

You can also observe injector performance on a scope. And, check its response to changes, in the air fuel ratio.

The injector scope pattern, will tell you how long the injector is on.

If you make the air fuel ratio artificially lean, by momentarily pulling off a vacuum hose. And/or artificially rich by feeding some propane into the manifold. Then, you should see a corresponding change, in the injector on time. Consequently, as the computer responds to input from, the (O2) Sensor. No change would tell you, either the (O2) Sensor is dead or there’s a problem in the computer.

A good injector should produce a, cone shaped mist of fuel vapor. So, if you see solid streamers in the spray pattern of fuel, the injector needs attention.

Also, check fuel pressure to see if the pump is weak, or the fuel pressure regulator is defective. A plugged fuel filter, can reduce fuel pressure. If fuel pressure is within specs, check the intake manifold vacuum. Next, check to see if there is an air leak, that’s upsetting the overall air fuel ratio. Finally, check for a leaky (EGR) Valve, or a leaky power brake booster.

In Summary: Engine Misfiring

The best way to avoid engine misfiring conditions, is through following the scheduled maintenance, in your manual. So, keep your vehicle’s engine, tuned according to factory specs. Plus, a yearly trouble code scan, can uncover any potential problems, before they become major faults.

“Thanks For Reading!”