Emission control systems help control fuel fumes, while cleaning engine producing exhaust gases.

So, emission control systems, have been efficient in reducing air pollution, caused by automotive engines.

And, emission control systems, depend on a series of chemical reactions, sensors and vacuum controlled solenoids, to operate correctly.

Also, emission control systems, rely on many other supporting systems, to function properly.

But, in time, chemical reactions fade as the devices lose their effectiveness. As a result, any of these failures, will cause a check engine light (CEL) to come on.

So, everyone asks, does idling waste fuel. The answer is YES! And, that’s why most vehicles today use, Stop/Start Technology. Because, we are producing greenhouse gases, that contribute to climate change.

Engine Generated Pollutants Come From Three Sources:

- Tailpipe exhaust

- Crankcase blow by fumes

- Fuel fumes, that evaporate from the fuel tank

Air Pollution Gases Include:

- Carbon monoxide

- Hydrocarbons

- Carbon dioxide

- Nitrogen oxide

Most Emission Control Systems Include:

- Air Pump

- Catalytic Converter

- Check Engine Light (CEL)

- Service Engine Soon Light (SES)

- Exhaust Gas Recirculation (EGR)

- Automotive Filters

- Gas Cap/Fuel Cap

- Evaporative System (EVAP)

- Mass Air Flow Sensor (MAF)

- OBD-II System

- Oxygen Sensor (O2)

Air Injection Systems (AIS) Function

So, the (AIS) is designed to introduce clean air into the engines exhaust, as it exits the exhaust manifold. Exhaust gases are at their hottest, as they leave the combustion chambers. So, introducing oxygen into the exhaust at this point, allows continued burning of the fuel mixture. Then, it travels down the exhaust system, and ultimately out the exhaust pipe.

So, There Are Two Different Types Of Emission Control Systems:

1. The Pump Type (AIR)

So, this type includes an air pump (AIR), commonly known as the smog pump.

First, engine exhaust (which contains unburned hydrocarbons and carbon monoxide) is routed into the (AIR) pump.

And, is then compressed and injected, through the Exhaust Manifold, and/or before the Catalytic Converter. The gases then combine with unburned hydrocarbons and carbon monoxides at higher temperatures, causing a chemical reaction.

Now, the spent exhaust is less harmful to our environment.

2. The Pulse Type (PAIR)

The second type of system known as the (PAIR) is a much simpler system.

Because, it only relies on the vacuum created in the exhaust stream, as it travels down the exhaust manifold.

As the engine cycles, this vacuum draws fresh oxygen, into the Air Injection lines. The air is then used to prolong complete exhaust burning.

This system should consist of a metal duct or hose approximately 1″ in diameter around the air cleaner. Then, leads to a metal air check valve, and then the exhaust manifold.

Your vehicle’s Under-hood Emissions Label, can provide you with all the information. Including, all the requirements of this emission control systems design, and its components.

Catalytic Converter

So, the catalytic converter looks just like a muffler. And, is located in the exhaust system, before the muffler. Inside the converter are pellets or a honeycomb, made of platinum or palladium. The platinum or palladium, is used as a catalyst.

As exhaust gases are passed over the catalyst, they are chemically oxidized or converted to carbon dioxide and water. But, as the converter works to clean the exhaust, it also develops heat.

And, the dirtier the exhaust, the harder the converter has to work. As a result, more heat is produced. So, if the converter works too hard to clean a dirty exhaust, it will destroy itself.

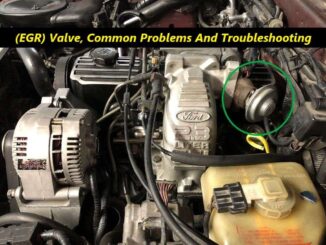

Exhaust Gas Recirculation (EGR) Valve

So, the (EGR) valve, has no recommended replacement or inspection interval. But, that doesn’t mean it won’t cause trouble.

The (EGR) reduces the formation of oxides of nitrogen, by diluting the air fuel mixture with exhaust. And, as an added benefit, the (EGR) also helps prevent detonation.

Filter Systems

1. The oil filter traps harmful debris from being recirculated, back through the engines lubrication system.

2. The air filter stops harmful dirt particles, from entering the engines air intake system.

3. The crankcase breather filter, cleans the air that is pulled into the engines crankcase.

4. The fuel filter cleans the fuel, before it reaches the fuel delivery system, namely the fuel injectors.

5. The canister filter cleans the air, entering the carbon canister.

Gas Cap (Fuel Cap)

So, a gas cap seals liquid fuel and fumes, from leaking from the gas tank.

The gas cap is also an integral part of the onboard diagnostics system (OBD-II) and emission control system.

A loose or damaged gas cap can allow fuel vapor to escape, triggering the check engine light (CEL).

Evaporative Emission System (EVAP)

The (EVAP) System Consists Of Five Parts:

- Fuel cap

- Fuel tank

- Carbon canister

- Canister purge valve

- Interconnecting lines and hoses

However, sealing the fuel tank, is not as simple as it sounds. Because, a fuel tank must have some type of venting. So, air can enter to replace the fuel leaving the tank.

So, if the fuel tank were sealed tight, the fuel pump, could create enough negative pressure, to collapse it. This system contains fuel fumes (hydrocarbons). But, instead of releasing them into the atmosphere, it stores them in a carbon canister. Then, the collected fumes are routed to the engine, where they can be burned.

Mass Air Flow (MAF) Sensor

So, a mass air flow (MAF) sensor, monitors air flow that enters the engine.

This is important for calculating the amount of fuel to add, to achieve the proper air to fuel ration.

On-Board Diagnostic System (OBD-II)

The service engine soon (SES) or check engine light (CEL) has several modes. It can also do a self check on the system.

Some Of The Trouble Codes Include, P0400-P0499

The System Can Also Show:

- A Normally working system

- A system that requires, prompt attention

- A system that needs, immediate attention

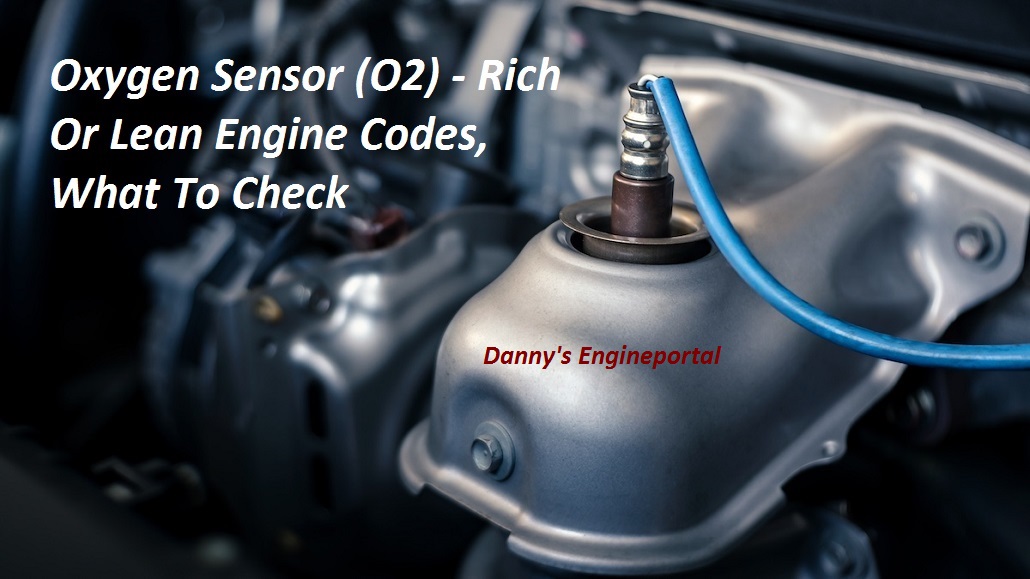

Oxygen (O2) Sensor

So, the (O2) sensor is responsible for measuring, how much unburned oxygen is in the exhaust. It is in constant communication, with your vehicle’s electronic control unit (ECU). And, it helps figure out what the right air to fuel ratio should be, for the best engine performance.

The (O2) Sensor Can Tell The (ECU) Whether A Fuel Mixture Is:

- Too lean. (meaning there is too much oxygen)

- Too rich. (meaning there is not enough oxygen)

In summary: Emission Control Systems

So, computerized controls, ensure the most efficient operation of emission control systems. In addition, computer controlled fuel injection systems, ensure a more precise air to fuel ratio. As a result, creating greater efficiency in combustion, while lowering pollutants.

Thank You !!