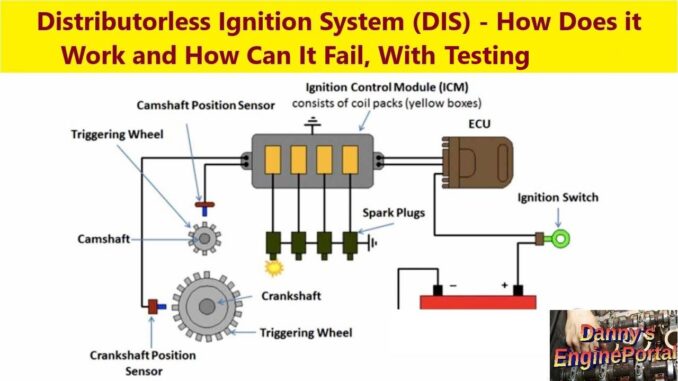

The distributorless ignition system is a completely solid state electronic system, with no moving parts.

So, with no distributor, there is no distributor cap, rotor or points to replace. And, no troublesome vacuum or mechanical advance mechanisms, to cause timing problems.

Because, the distributorless ignition system, uses a engine control module, ignition control module and multiple ignition coils.

The Components Of A Distributorless Ignition System Are:

- Ignition Coils

- Spark Plug

- Ignition Control Module or Engine Control Unit

- Ignition Switch

- Battery

- Crankshaft Triggering Device

- Camshaft Triggering Device

So, How Does The Distributorless Ignition System Work

When we turn the ignition switch, the current from battery flows through the switch, to the engine control unit. Then, the engine control unit processes data from sensors and calculates the ignition timing. Triggering wheels mounted on the camshaft and crankshaft, identify the position of the crankshaft and camshaft.

The position sensors, are equipped with a magnetic coil, which generates a magnetic field. When the gap of a triggering wheel, comes in front of the position sensor, a fluctuation in the signal occurs. These signals then stop or start the flow of current, to the primary winding of the coil.

So, What Can Cause The Distributorless Ignition System To Fail

Over time, the evolution of the distributorless ignition system, has provided a number of benefits. But, that does not mean, they are trouble free. Failures can and do occur, for a variety of reasons. So, knowing how to identify and diagnose, common ignition system problems, can save you a lot of guesswork.

This will help the next time your engine cranks, but fails to start or one that runs, but is missing. If an engine cranks, but will not start, is it fuel, ignition or compression? Ignition, is usually the easiest of the three to check. Because, on most engines, all you have to do is pull off a plug wire.

Then, check for spark when the engine is cranked. But, on the coil on plug system, there are no spark plug wires. So, you have to remove a coil and use a plug wire or adapter, to check for a spark.

How To Testing The Distributorless Ignition System

First, if there is no spark in one cylinder, check another. No spark in any cylinder, would most likely indicate, a failed module or crankshaft position sensor. Because, many engines with electronic fuel injection, use the crankshaft position sensor signal, to trigger the injectors.

But, if there is no spark and no injector activity, the problem is likely in the crankshaft position sensor. And, no spark in one or two cylinders that share a coil, would tell you a coil has probably failed. The coils in a distributorless ignition system, function the same as those, in ordinary ignition systems.

So, testing is essentially the same. But, the driveability symptoms, caused by a weak or dead coil, will be limited to one or two cylinders. Rather than all the cylinders.

Other Possible Issues

A low manifold absolute pressure sensor output voltage, or a coolant temperature sensor that always reads cold. Will allow more spark advance than normal. This, in turn, may cause detonation or spark knock problems, when the engine is under load. And, a faulty knock sensor or an (EGR) valve that is not working.

In contrast, a high manifold absolute pressure sensor output voltage. Or an incorrectly throttle position sensor, can have the opposite effect. This would cause the spark control system, to retard timing more than normal. Retard timing, will reduce performance and fuel economy.

In Summary: Distributorless Ignition System

Do not forget, that ordinary secondary ignition problems, can cause misfires. Just the same as a conventional ignition system. And, a bad spark plug wire or a fouled spark plug, will act just like a weak or bad coil.

The Distributorless Ignition System, Has Several Advantages Over The Conventional Distributor Type Systems.

- Less voltage loss, from the coil to the plug.

- Fewer connections and the elimination of the distributor, cap, rotor, points and wires.

So, the evolution of ignition systems, has provided a number of benefits. As a result, drivers with newer systems enjoy better fuel efficiency, more reliable operation and reduced maintenance costs.

Thank You!