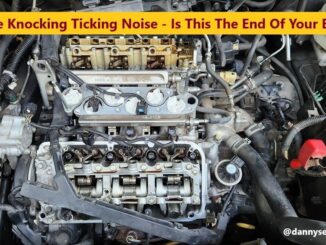

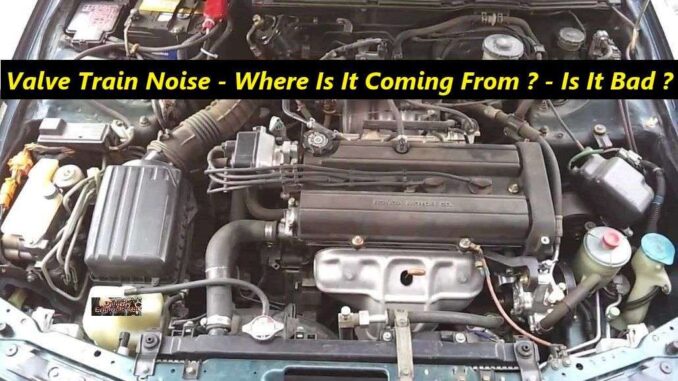

Valve train noise, is usually due to excessive clearance, between two internal engine parts.

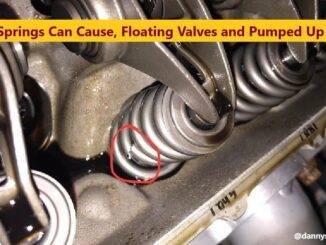

Each valve utilizes, a valve spring that returns it to its, original closed position.

So, if a valve spring has broken or a camshaft lobe is worn down. Then, it will cause the engine to create a tapping or clicking sound, due to the excess clearance.

Valve Train Noise, is similar to a clicking sound, of a sewing machine. And, the sound frequency of the valve train noise, is one half of the crankshaft speed.

Where Is The Noise Actually Coming From

A ticking lifter is one very common, valve train noise. Also, if the engine has solid (mechanical) lifters fixing this, usually requires an adjustment.

Most likely, because the amount of valve lash or free play, is far too excessive. The problem with diagnosing and correcting valve train noise, is that there are many components that can cause noise.

As a result,, not every noisy valve train, is suffering from improper adjustment. For this reason, even after the valves are adjusted properly, the engine may still be noisy. If this is the case, then the problem, is not with the valve lash. On the other hand, a mechanical failure due to wear, is probably causing the sound.

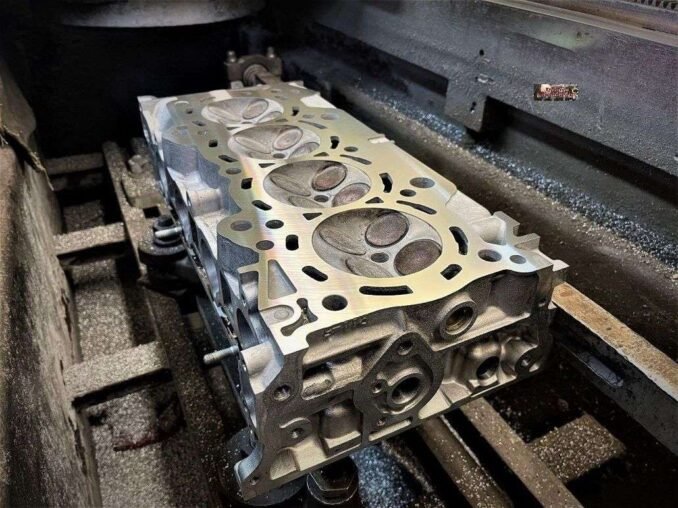

Though there are many possible causes, the valve lifter is often, the source of the noise. Another cause of valve train noise can be, the result of machining of the cylinder head, and valve seats. Because, this changes the rocker arm geometry.

Many mechanics think that this is caused by, faulty hydraulic lifters. That is incorrect. The lifter is only responding to the conditions, and trying to adjust for them. That’s why, it is critical to make sure that the valve train, is the culprit.

It Is Important To Remember That, Several Different Conditions Can Produce A Noise. And, Some Sound Identical To That Caused By, A Failed Or Failing Valve Lifter.

Some of these conditions include:

- Lack of lubrication, between the rocker arm and the pushrod

- Lack of lubrication, between the rocker arm and the end of the valve stem

- Excessive valve guide to valve stem clearance

- Badly worn valve tips, and/or rocker arm pads

- Worn camshaft lobes

- A loose valve seat, on heads with inserts

- A warped valve

- Excessive clearance between, the lifter and the lifter bore hole, in the block

- A loose rocker arm shaft

- A broken, valve spring

So, if the engine noise is not caused by, one of the listed issues. Then, it may be a hydraulic valve lifter.

Isolating The Noise

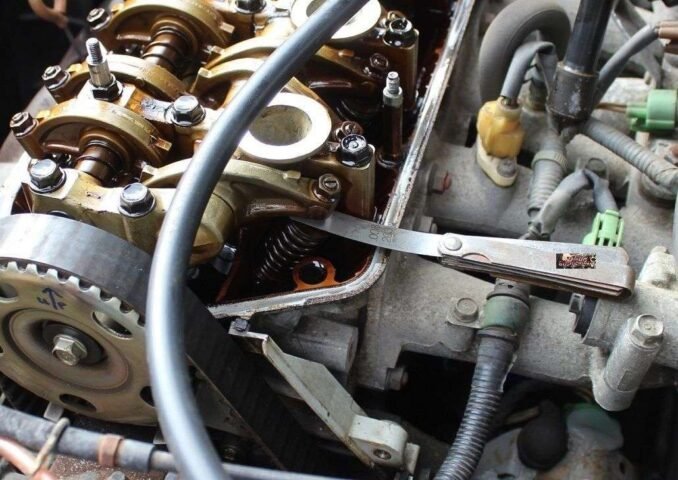

Now you will need to isolate the failed lifter. A simple method, is to use a piece of garden hose. Remove the valve covers. With the engine running, place one end of the hose near the, spring retainer of each intake and exhaust valve. Put the other end of the hose to your ear. Consequently, it will be very apparent which is, the offending valve lifter.

Other ways to find a faulty valve lifter. With the engine shut off. Push down on each of the rocker arms, on the pushrod side. If the rocker arm is free to move or there is a spongy feeling. It is a good indicator that, the valve lifter is leaking down too fast, or not retaining the oil.

Once you locate the lifter that is causing the noise, you will need to determine the reason for its malfunction.

There Are Four Types Of Valve Train Noise, You May Experience. An Inoperative Or Failing Valve Lifter, May Cause Any One Of Them:

Loud, Rapping Sound

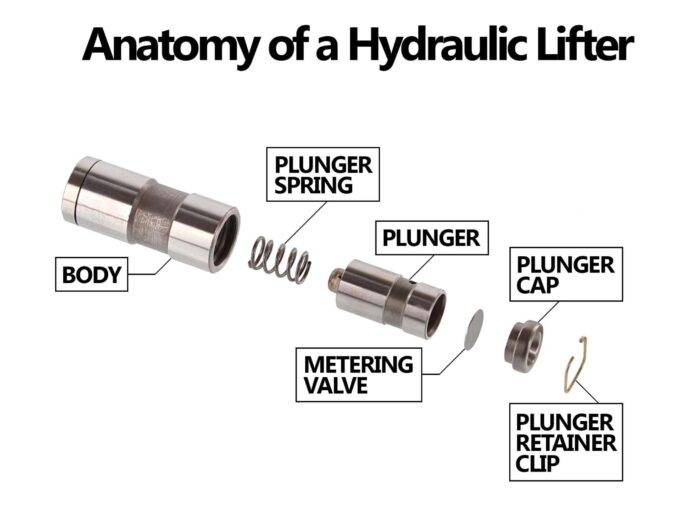

So, a stuck plunger inside the body of the lifter, could also be the cause. This is usually due to excessive varnish between, the plunger and body.

Also, by dirt or other foreign materials wedged between, the plunger and body. Another cause of a loud rapping sound is, an excessively worn base or foot, on the lifter itself.

Moderate Ticking Noise

This can be the result of excessive varnish. Wear on the bottom of the lifter mat, could also be a source of noise. Lack of zinc in oil at initial break in. The noise level depends, on the amount of varnish, and the degree of wear. Two other causes of a moderate ticking noise are, excessively fast or slow leak down.

Slow leak down, generally will cause the engine to be noisy only when, cold and the oil is thick. With fast leak down, the valve train will be noisy, when the engine is warm. Fast leak down, will also occur, if the ball check in the lifter, fails to seal.

Intermittent Ticking

This type of noise, is hard to locate, by its very nature. There will be a few ticks, and then it will be quiet. But, the noise will come back, after a short period of time.

The usual cause of intermittent clicking, is a very minute piece of dirt. Because, it holds the ball check off the seat for a few seconds, and then passes through. In rare cases, the cause of the sound, is a pitted or flat spotted ball check.

General Valve Train Noise

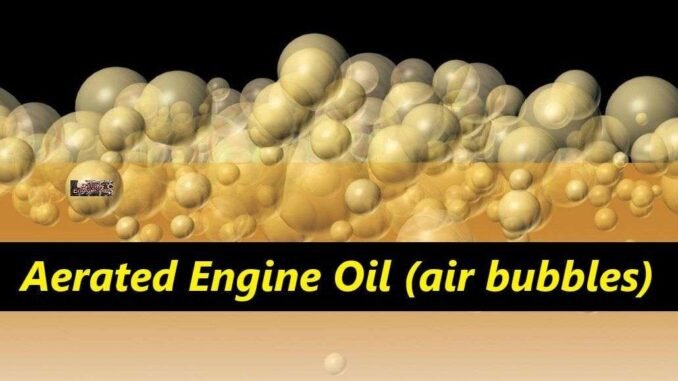

Sometimes the sound is throughout the entire valve train. And, is usually the weight of the oil or the oil supply itself. Too much oil in the crankcase, will cause foaming and aeration. When air gets into the lifters, they will fail to operate properly. Insufficient oil supply to the lifters, can also cause general valve train noise.

This could be the result of:

- Too little oil in the crankcase

- An oil pump not operating properly

- Clogged main oil gallery lines

Excessively thick engine oil will cause, the entire valve train to make noise, when cold starting an engine. The noise will diminish, when the oil warms up, and starts to flow properly. So, an engine with thick oil, will be more prone to noise, in colder weather than, during the summer months.

Conclusion

So, as a mechanic you hear the phrase “my engine is making a strange noise” relatively often. Though there are many possible causes, the valve lifter, is often the source of the noise.

BY DANNY BENDER