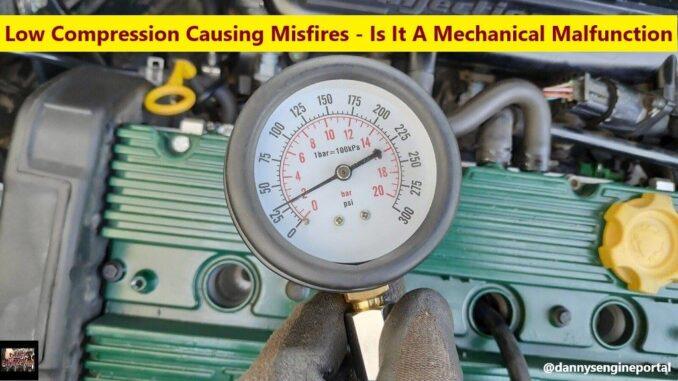

First, low compression can be caused by a number of different issues, resulting in a misfire.

So, let’s say you have ruled out ignition and fuel delivery, as the cause of the misfire.

Then, that leaves low compression as the underlying cause of the misfire. But, there are many reasons, why low compression might exist in your engine.

Sometimes, there will be low compression, in just one cylinder. And, other times, there will be low compression, in all cylinders.

First, you have to understand the possible causes, for low compression.. Then, fix or replace whatever is damaged and the cause.

Above all, one of the best ways to prevent a misfire from happening, is to perform proper car maintenance.

When you have a misfire from low compression. Usually, the first thing to happen is a check engine light (CEL) and a diagnostic trouble code (DTC) spring up.

A flashing check engine light (CEL) and a P0300 to P0312 diagnostic trouble code (DTC). Is a surefire indication, that one or more cylinders are misfiring. An occasional misfire may pass unnoticed, but a steady misfire is hard to miss. The engine usually feels rough, lacks power and uses more fuel than usual. And, sometimes a misfire may feel like a vibration.

Above all, a misfire also will cause a huge increase, in hydrocarbon (HC) emissions. And, that can cause a vehicle, to fail an emissions test. A misfire that turns on the check engine light (CEL) and logs a diagnostic trouble code (DTC). Those are the easiest to diagnose.

The OBD-II system will identify the cylinder(s) that are not contributing to their normal dose of power. As a result, setting a diagnostic trouble code (DTC), that corresponds to the firing order. So, a P0303 code, for example, would tell you that the No. 3 cylinder is misfiring. To figure which cylinder is No. 3, refer to a diagram of the engine’s firing order.

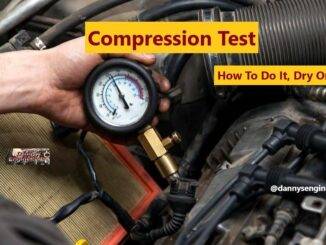

This Kind Of Failure Is Easy To Check, Using A Compression Tester

So, if no compression is present, in any one or more cylinders, it means a mechanical malfunction has occurred. Engine mechanical testing, is another great way to spot problems.

Consequently, a misfire that turns on the check engine light (CEL) and logs a diagnostic trouble code (DTC), are the easiest to diagnose. The OBD-II system will identify the cylinder(s), that are not contributing to their normal dose of power and set a diagnostic trouble code (DTC).

Causes Of Low Compression, In One Cylinder:

Carbon Deposits On Intake Valves And Valve Seats

So, carbon build up can hamper the performance of any engine. Don’t let this carbon build up be the cause of your problems. Like, a misfire causing a check engine light (CEL), loss of power, or loss of fuel economy.

Broken Valve Spring

So, if you’re currently having a misfire, low compression, or strange ticking or tapping noises, you may be in trouble. Broken valve springs can cause, obvious performance and efficiency issues. When a spring breaks, it may collapse just enough, to allow the valve to drop into the cylinder.

And, in an interference engine, the piston may strike the valve. In addition, the valve stem locks or keepers may release the valve and allow it to drop into the cylinder. Resulting in severe damage to the piston, cylinder head, and other nearby parts.

Bent Push Rod

A bent push rod can cause several symptoms in an over head valve (OHV) engine. Including poor engine performance, reduced fuel economy, rough idling, misfiring, increased emissions, and low compression. The push rod is an important part of the over head valve (OHV) engine.

Push rods are used in over head valve (OHV) engines, because they are simple and reliable. The push rod actuates the rocker arm, which in turn opens and closes the valves.

Dropped Valve Seat

Usually dropped valve seats, are caused from cooling system issues. For some reason the engine, has experienced extreme heat. Aluminum and steel expand at different temperature rates. So, the aluminum cylinder head over expands and then, the steel valve seat press in fit is lost.

Other Low Compression Causes May Include:

- Cracked Cylinder Wall

- Gasket Issues

- Holes in Piston

- Damaged Timing Belt

- Valve Problems

- Worn Pistons or Piston Rings

A leak down test or cranking compression test, can be used to see if the cylinder, is holding or pumping up normal pressure. As a rule, most engines should have, 140 to 160 lbs. of cranking compression, with no more than 10% difference, between any of the cylinders.

Causes Of Low Compression, In All Cylinders:

Broken Camshaft

A broken camshaft is a serious engine problem, that can lead to a variety of issues. Including a misfire, loss of power, and even complete engine failure. It’s often caused by lubrication problems, improper installation, or mechanical failure, such as a connecting rod striking the camshaft. Early detection of symptoms like ticking noises, a check engine light (CEL), and poor performance is crucial. And, can prevent further damage and costly repairs.

Broken Timing Belt or Chain

A broken timing belt or chain will immediately cause your engine to stall. And, potentially lead to significant engine damage, especially in interference engines. Symptoms can include a loud bang or grinding noise, followed by the engine refusing to start. If your engine is an interference type, it’s even worse. Because, a broken timing belt or chain can cause the pistons to collide with the valves. As a result, leading to bent valves, damaged pistons, and even a cracked cylinder head.

Fuel Washed Cylinders

There is a condition that adds to many failures of rebuilt or re-rung engines, generally referred to as “fuel wash”. It is caused by engine flooding at initial startup or in early operation, of a newly rebuilt engine. This phenomenon can cause very serious damage to the cylinder bores, pistons, and piston rings. And, can result in a misfire.

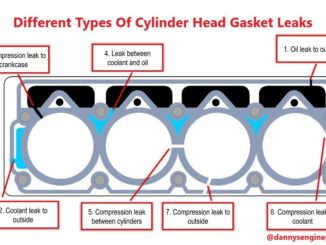

Blown Head Gasket

A blown head gasket is a serious engine problem where the head gasket, which seals the combustion chamber, fails. This can lead to various issues, including coolant and oil leaks. Also, white or blue smoke from the exhaust, and engine overheating. It’s crucial to address a blown head gasket as soon as possible, to prevent further engine damage.

Other Low Compression Causes May Include:

- Worn Piston Rings

- Bad Intake or Exhaust Valves

- Flat Camshaft Lobes

- Broken Piston Rings

Fouled Spark Plugs, From Carbon And Oil Deposits

So, if you have any of the above causes, the cylinder head will have to be removed. Another reason for removing the cylinder head, is if you find spark plugs that are, heavily fouled with oily deposits. Oil leaking past worn valve guides or seals, is usually the culprit.

Installing new spark plugs will cure the symptom, but, not the cause. Consequently, the permanent fix, is to replace the valve guides and install new, valve guide seals. However, this is not the fix, for low compression.

A spark plug that shows heavy whitish to brown deposits, may have a coolant leak. And, may be either past the head gasket or through a crack in the combustion chamber. This type of problem, will only get worse and may soon lead to even greater problems.

Also, a cylinder will not fire normally, if the valves are not opening and closing properly, due to a weak or broken valve spring or a rounded off cam lobe.

In Summary: Low Compression

So, when compression gets below 90 pounds, the cylinder could misfire. You may need to do some, mechanical testing.

TIP: You can also do, a running (dynamic) compression test.

Consequently, if you find that there’s low compression, you need to check all possible areas, where the problem may be. Including, the gaskets, valves, pistons, and cylinders. As a result, any type of damage in these parts, can add to your problem.

Thank You !!