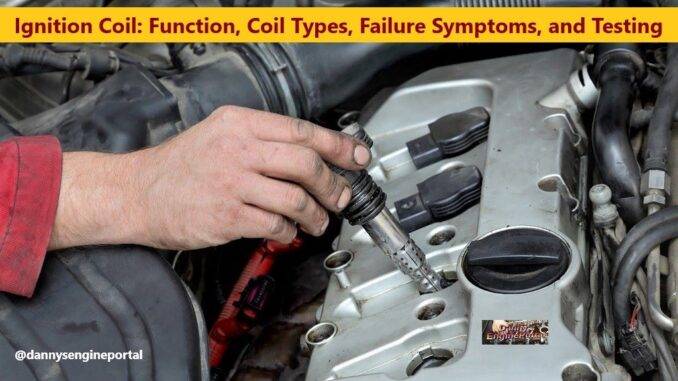

The function of the ignition coil, is to produce a high voltage, from a low voltage.

Because, the high voltage from your ignition coil, is needed to ignite the fuel, and start the engine.

So, for an ignition coil to work, it has to have battery voltage, at its positive terminal. Also, it needs to be grounded, on and off, by the ignition module or circuit. Consequently, if it is not producing a spark, the coil is defective and needs to be replaced.

So, the ignition coil is very rugged and reliable. But, it can fail, for a variety of reasons.

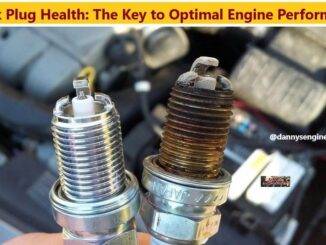

Heat and vibration, can damage the coil windings and insulation. As a result, causing shorts or open circuits, in the primary or secondary windings. But, the number one killer of ignition coils, is too high a voltage. Usually, caused by, bad spark plugs or plug wires.

How Does The Ignition Coil Function

So, inside the coil, are two sets of windings. The primary coil windings, containing hundreds of turns, of heavy wire. While the secondary side, contains thousands of turns, of fine wire. In older vehicles, a single coil, would service all the spark plugs and use a distributor. In modern systems, the distributor is omitted. Because, the ignition coil, is now electronically controlled. But, with all this new technology, come new issue to solve.

Some Of The Ignition Coil Failure Symptoms, Include:

- Backfiring

- Poor Fuel Economy

- Vehicle Stalling

- Poor Power, Engine Jerking, Rough Idling,

- Engine Does Not Start

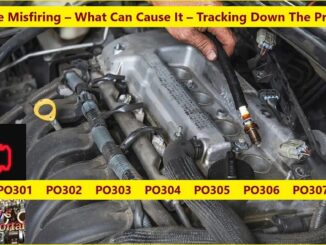

- Engine Misfires

- Poor Acceleration or Loss of Power

- Engine Control Unit (ECU), Turns on Limp Home Mode

- Diagnostic Trouble Codes (DTC)

If the coil malfunction is causing your engine to misfire, this will allow raw fuel to enter. As a result, permanently damaging, the catalytic converter.

Take steps to check for oil leaks, moisture and spark plug issues, to prevent serious engine damage.

So, the most likely cause, is a oil leak from the valve cover gasket. On many (COP) style engines, the spark plug and ignition coil are mounted, inside a spark plug tube. This tube is sealed in place, around part of the valve cover.

Overtime, the seal between the valve cover and that spark plug tube can fail. As a result, causing oil to leak in and fill up around the spark plug, and ignition coil. This in turn, can lead to, spark plug and coil failure.

The Most Common Ignition Coil Types

There Are Basically, Four Main Types Of Coils:

1. Conventional

So, with the conventional “breaker point” type ignition systems. The primary circuit receives power, from the battery through a resistor. Current flows through the windings of the primary coil, creating a magnetic field. Then, when the points are opened, the current’s electrical circuit is broken. As a result, collapsing the magnetic field.

The force from the collapse, crosses the windings of the secondary coil, and creates an electrical current.

The current then flows into the distributor cap and eventually, into the spark plugs. But, these early fully mechanical distributor systems, had their problems. The ignition points, would break down and change the spark timing, messing up engine efficiency. As a result, they had to be replaced, as often as every 12,000 miles.

2. Electronic

So, this type of ignition, is very similar to the, conventional system. But, instead of a distributor cam and points, the electronic system uses, a pickup coil to signal the control module.

Doing so, increased reliability. But, the solid-state switches, still took their marching orders, from the distributor shaft.

Distributor shafts, would tend to develop a certain amount of “lash” or slop after 120,000 or so miles. Since gear wear would always be an issue to proper spark timing, mechanical ignition systems had to evolve.

3. Distributor-less (DIS)

So, in a distributorless ignition system (DIS), its design allowed more energy, to be available from multiple coils. Also, there are, three or more mounted together, in a coil pack.

This system uses a magnetic triggering device, to determine engine speed and crankshaft position. This system determines spark timing, based on two shaft position sensors, and a computer.

The crankshaft position sensor (CKP), and the camshaft position sensor (CMP). These sensors, continually monitor both shafts’ positions and feed that information, into a computer.

4. Coil On Plug (COP)

So, the coil on plug (COP) ignition system, includes all the electronic controls, found in a (DIS) ignition system. But, instead of two cylinders sharing a single coil, each (COP) coil services, just one cylinder. As a result, some (COP) ignition systems, generate as much as 50,000 volts, and much hotter, stronger sparks.

The coil mounts directly on top of the spark plug. As a result, the need for spark plug wires, is no longer an issue.

The Top Ignition Coil Failure Reasons Include:

- Bad spark plugs

- Bad plug wires

- Too High A Voltage

How To Test For Spark

Above all, never pull off a plug wire or the coil’s high voltage output wire, to test for a spark. Besides risking a severe shock, an open plug wire or coil wire, will increase the voltage demands on the coil. Furthermore, to the point where, it may damage the coil. So, the only safe way to test for spark, is to use a spark plug tester tool.

Conclusion

So, heat and vibration, can damage the coil windings and insulation. As a result, causing shorts or a open circuit, in the primary or secondary windings. Finally, new spark plugs, will help ignition coils last longer.

BY DANNY BENDER