“Choose Your Variable Valve Timing VVT Help Topic Below”

- Variable Valve Timing (VVT) – Function And Its Advantages

- (VVT) Variable Valve Timing: Enhancing Engine Performance

- Variable Valve Timing (VVT) – Benefits & Advantages Explained

(VVT) adjusts valve timing based on engine revolutions per minute (RPM). And, optimizes performance across a wide range of speeds. At low (RPM)s, (VVT) can optimize for fuel efficiency. By keeping valves open for a shorter duration or closing them earlier. While at high (RPM)s, it increases valve lift and duration to improve power output.

Low (RPM) (Engine Efficiency and Emissions)

Valve timing:

The system can retard (delay) the valve opening and closing times to improve low-end torque and fuel economy.

How it works:

By closing the intake valve sooner, it traps a better air fuel mixture and reduces pumping losses. It can also achieve an effect similar to an (EGR) system to control combustion temperatures and reduce (NOx) emissions.

High (RPM) (Engine Power)

Valve timing:

The system can advance (speed up) the valve opening and closing times, to increase the time the valves are open.

How it works:

Opening the valves earlier and for a longer duration (increased lift and duration) allows the engine to breathe more freely. Letting more air and fuel into the cylinders. This is crucial for producing more power at high engine speeds.

Continuous vs. Discrete Systems

Discrete:

Older or simpler (VVT) systems might use two or more fixed timings. Switching between them at a specific (RPM) threshold (e.g., one timing for below \(3500\) RPM, another for above).

Continuous:

Modern systems can continuously and infinitely adjust the valve timing. And, optimize performance for every engine speed and condition.

So, How Is It Controlled

- The (ECU) uses sensors to monitor engine speed and other factors.

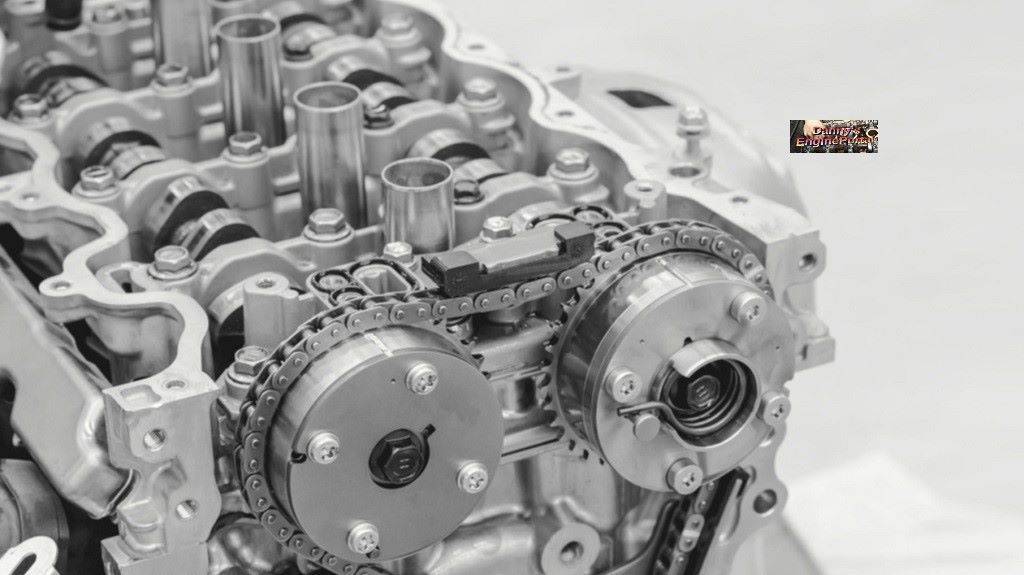

- The (ECU) sends signals to hydraulic actuators. Which use oil pressure to rotate the cam relative to the crank, changing the timing.

Thank You !!