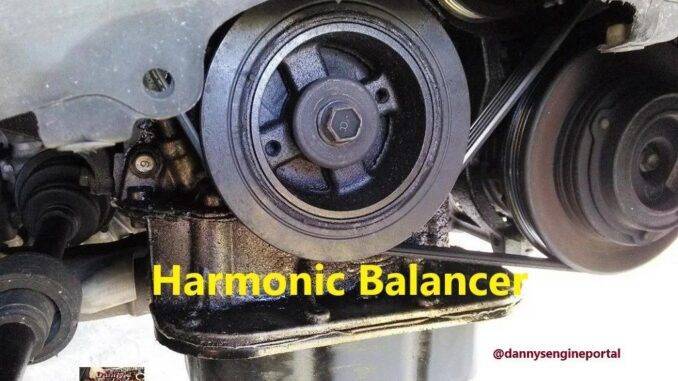

So, what is the main function of the harmonic balancer? Well, it is to absorb and reduce, harmonic and torsional vibrations from the engine.

Consequently, your harmonic balancer is mounted, on the front of your engine. And, is usually connected, to a crankshaft pulley.

But, they have other names as well. Such as, vibration damper, crankshaft pulley damper, crankshaft balancer, and crankshaft harmonizer.

So, the harmonic balancer does not fail very often. But, when it does, it can cause major damage.

Extreme vibrations, especially at high engine speeds, can cause faster wear, and damage to engine parts. The speeding up and slowing down of the crankshaft, also produces torsional vibration or twisting forces. As a result, putting stress on the crankshaft and the connected parts. And, if the stress is great enough, the crankshaft will eventually fail.

So, each time a cylinder fires, the connecting rod applies, rotational force to the crankshaft. While, at the same time, the crankshaft is in the process of, pushing another piston up.

So, there are tremendous counteracting forces, being applied to the crankshaft. Between each power pulse, the crankshaft twist, tends to spring back. As a result, there’s really a forward and backwards twist. For this reason, the crankshaft is designed to bend slightly. Consequently, this is to handle, the counteracting forces and prevent damage.

There Are Basically, Two Types Of Harmonic Balancers:

One, With A Rubber Isolation Ring, And Two Basic Elements

Inertial Mass Element

The inertial mass, is made up of an outer ring and an inner hub. And, that connects to the crankshaft. The outer ring houses the mass, to cancel out the vibrational forces.

Energy Dissipating Element

Between the two metal parts, is the energy dissipating element. That material, is a rubber or elastomeric compound. This ring of rubber, allows the two metal parts, to go out of phase, as it absorbs the vibrations.

And, One With A Fluid Isolation System

A fluid isolation system is similar. But, instead of using a rubber ring, it relies on a thick silicone fluid. Similar to the viscous clutches, used in radiator fans and (AWD) center differentials.

What Is The Most Common, Harmonic Balancer Failure

The rubber isolation ring deteriorates completely. As a result, the pulley completely dislodges, from the center portion of the balancer.

Heat, Seems To Be The Biggest Cause Of Failures

The constant twist/untwist movement, causes the rubber to heat. The most damaging cause, would be the engine, getting too hot. That extra heat, can dramatically accelerate deterioration, of the rubber isolation ring. In addition to heat deterioration, fluid contamination, can also accelerate decomposition of the rubber isolation ring.

Consequently, you can have an engine oil leak or coolant leak that flows, onto the harmonic balancer.

The oil and coolant contamination, softens the rubber, causing a change in vibration frequency. Most people with a stethoscope, can pick up the vibrations of a bad harmonic balancer. In some cases, you can also see, the belt vibration. As the rubber belt deteriorates even more, you’ll notice engine vibration at higher (RPM)s.

Usually A Problem With The Harmonic Balancer, Will Produce A Few Failure Warning Signs:

Engine Vibration

One of the first symptoms of a potential problem, is engine vibration. If the harmonic balancer can no longer properly absorb the harmonic vibrations, the engine will shake badly. At some point, the shaking will become even more apparent. As a result, making it dangerous to the engine, at high speeds.

Worn Seal Surface, Causing Leaks

Heat and engine vibration, can cause the seal to become hard, and loose its sealing ability. As a result, allowing residual engine crankcase pressure, to force oil past the seal, and out from the engine. Because the seal rides against the inner hub of the balancer, it can cause grooves in the seal surface.

Misaligned Timing Marks

Another symptom of a potential problem with the harmonic balancer, is misaligned timing marks. If the layers separate or slip, the timing marks can shift. This will make it, difficult if not impossible, to properly time the engine, with a timing light.

Transmission Damage

If a damper is no longer able to absorb crankshaft vibration, the destructive forces will start to, attack the transmission. The vibrations could damage, the input shaft, bearings, planetary gears and more.

Stripped And Or Damaged, Damper Bolt Or Threads

Another common issue, is the hold down bolt coming loose or breaking. In fact, some engines are more prone than others for this problem. It may be from the wrong torque or just engine vibration. But, at some point it could develop into, a wobble in the pulley or even, severe engine damage.

Alternator And Or Power Steering, Pump Failure

A belt tensioner or de coupler pulley, can take only so much vibration. While the damper may only flex 1º or 2º, this helps to take a lot of strain off attached parts.

A Squeaking Noise You Just Can’t Diagnosis

So, a loose or damaged damper, can make a squeaking noise as it rotates.

Elongation Damage Of The Damper And Or, Crankshaft Keyway

A worn keyway, could cause the harmonic balancer to fall off. As a result, causing the engine to overheat, and even more damage.

Irregular Idle

So, some dampers work hardest, during idle. If a damper has failed, the idle may vary, as the dampening mass moves around.

Removal Errors ( Use The Correct Tools )

So, always use the correct procedure and tools, to pull the damper from the engine. To replace the timing belt on most vehicles, the damper has to come off. The most important thing to remember, is never put pressure on the outer ring with a hammer.

Install Errors ( Use The Correct Tools )

Above all, never use a hammer to hit the damper. Because, this could damage, the internal parts. Instead, always use the correct tools to install a damper. Because, not using the correct tools, can damage the damper and the crankshaft. The most common install error, is using the center bolt, to pull the damper on the nose of the crank. That’s why, it is common, to strip the threads in the crankshaft.

Installing The Wrong Belt

A belt that is too tight, can cause extra stress, on the accessory belt drive items. As a result, the harmonic damper can fail, from the extra tension. You may also see this, as a flutter in the tensioner arm.

Conclusion

So, a simple way to think of the harmonic balancer, is like a massive stress reliever. Because, it absorbs the violent torsion of the modern day engine.

BY DANNY BENDER