Engine bearing clearance, is very important and can cause early failures if not correct.

Engine bearings should operate with, the least amount of engine bearing clearance as possible.

So, tighter oil clearances, produce less peak loading on the bearings. As a result, the engine runs smoother, with less vibration.

Above all, correct Engine Bearing Clearance, is vital to the life of your engine.

So, You Can Mix Bearing Sizes, To Achieve Desired Oil Clearances

In order for bearings to maintain a stable oil film, there must be a perfect match with:

- Engine bearing clearance.

- Oil viscosity.

- Engine operating temperature.

- Crank surface finish and geometrical alignments.

Just remember that bearing size, needs to be uniform. Also, a general rule of thumb for determining oil clearance is, .001 of clearance for every inch of shaft diameter. Ex .001 x 2.00 shaft diameter. = .002 oil clearance.

For Clearances Smaller Or Larger Than The Rule Of Thumb, Refer To The Factors Listed Below

Factors for, tighter engine bearing clearance:

- Smaller journals.

- Lower viscosity oils.

- Surface finishes min 4 RA.

- Near perfect crank and engine block geometry.

- Higher engine operating temperature, due to decreased oil flow.

- Perfectly balanced cranks.

Factors for, looser engine bearing clearance:

- Larger journals.

- Higher viscosity oils.

- Surface finishes, rougher than 5 RA.

- Not so perfect crank and engine block geometry.

- Lower engine operating temp, due to increased oil flow.

- Weaker housing bores, causing distortion at high (RPM).

NOTE: The oil escape from a pressure fed bearing, increases by roughly the square of the engine bearing clearance. Thus, a clearance of 0.002” (0.050mm) can pass almost, twice as much oil as with 0.0015” (0.038mm).

So, if the oil pump capacity cannot meet this demand, the pressure will fall. This will result in bearing failure. This illustrates the importance of, accuracy in fitted bearings.

Multi-viscosity synthetic engine oils, flow more easily than, conventional straight weight oils. Even, at both low and high temperatures. So, they can handle cold starts, as well as elevated operating temperatures, (which is really important with turbochargers).

Therefore, to reduce friction and improve fuel economy; most engines are factory-filled with 5W20 or even 0W20 oil. In addition, combined with tighter engine assembly tolerances; these oil and bearing combinations, work relatively well for everyday driving.

Especially, if the engine has a flat tappet camshaft, that requires plenty of ZDDP in the additive package.

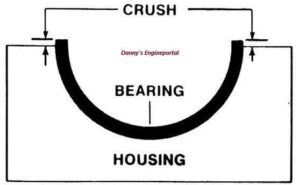

Excessive Bearing Crush

Appearance:

- Extreme wear areas visible along the bearing surface, adjacent to one or both of the parting line.

Damaging Action:

- A small portion of the bearing extends, just a little beyond the edge of the bearing housing.

So, the bearing is forced against the housing, when tightened in place. Consequently, that portion of the bearing which extends beyond the housing, is called “crush”.

So, when there is too much crush, it causes the bearing to bulge inward, at the parting faces. This bearing distortion is called “side pinch.”

Possible Causes:

- Bearing caps were filed down.

- Excessive torquing.

- Not enough shims.

Engine Bearing Clearance, Corrective Action:

- Rework the bearing housing of the engine block, if it has been filed down.

- Also, replace the connecting rod, if its bearing cap has been filed down.

- Check journal surfaces and regrind if necessary.

- Above all, Install the new bearing and follow proper installation procedures. Never, file down bearing caps and always use, the recommended torque wrench setting.

- Correct the shim thickness (if applicable).

- Also, check for out-of-roundness of the inside diameter of the assembled bearing. Use an out-of-roundness gauge, inside micrometer, calipers or Prussian blue. Consequently, to assure that any out-of-roundness, is within safe limits.

Insufficient Bearing Crush

Appearance:

- Highly polished areas are visible, on the bearing back or on the edge of the parting line. Areas of pock marks or build-up, due to metal transfer between bearing and housing. This is commonly referred to as “fretting”.

Damaging Action:

- So, a bearing with insufficient crush, will be loose. And, will be therefore free, to work back and forth within its housing.

- Because, of the loss of radial pressure, there is inadequate contact with the bearing housing.

- As a result, impeding heat transfer away from the bearing.

- Also, the bearing overheats, causing deterioration of the bearing surface.

Possible Causes:

- Filed down parting faces, in a mistaken attempt, to achieve a better fit, thus removing the crush.

- Due to dirt holding open bearing caps.

- Insufficient torqueing during installation; (be certain bolt doesn’t bottom out, in a blind hole).

- The housing bore was oversize, or out of round.

- Over use of shims.

Engine Bearing Clearance Corrective Action:

- Clean mating surfaces of bearing caps and inspect, for nicks and burrs prior to assembly.

- Check journal surfaces, for excessive wear and regrind if necessary.

- Check the size and condition of the housing bore and recondition if necessary.

- Correct shim thickness (if applicable).

- Install new bearings, using correct installation procedures (never file bearing parting faces).

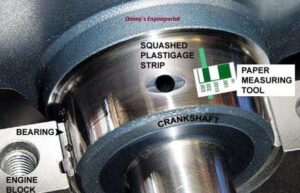

Using “Plastigage”

So, most auto parts stores have it available. Also, it comes in, various different crush dimensions. Consequently, to coincide with, the engine bearing clearance figures for your engine. Start with loosening the bolts of, bearing cap number one. Remove the bolts along with the cap (and bearing). Finally, wipe all traces of oil, from the crankshaft and the bearing surfaces.

Next, tear off a short piece of Plastigage (it’s sold in a long, thin paper envelope). Place a section of Plastigage on the center of the crankshaft journal, oriented front to back or diagonally.

Install the bearing cap and bolts. Torque to specs, then loosen the bolts and remove the cap. As a result, you’ll find the Plastigage, has crushed on the crankshaft journal.

Use the envelope the Plastigage was packaged in. You should find a scale on one end. Compare the scale to the crushed Plastigage on the bearing journal. This is the clearance figure. Now if the clearances are within specs, you can move forward. Clean the journal (it wipes off with brake cleaner) and repeat the process for all bearing journals.

Finally, use the same format, for checking connecting rod bearing clearances.

Conclusion

So, the oil doesn’t care what kind of bearing and shaft it is lubricating. But, it needs to maintain enough oil film, between the two surfaces. Consequently, to provide hydrodynamic lubrication and prevent, metal-to-metal contact.

BY DANNY BENDER