So, valve lifters, come in either hydraulic or mechanical (solid). But, what is the real difference, between them.

Both, hydraulic and mechanical (solid) valve lifters, have the same job, but do it differently.

They both follow the contour of the camshaft lobe, and transfer that motion, to open and close the valves.

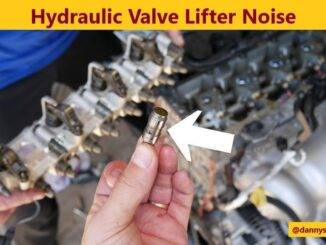

Both, hydraulic and mechanical (solid) valve lifters, look similar, from the outside. But, it’s what’s inside the lifter, that makes all the difference.

So, valve lifters are either, hydraulic or mechanical (solid). Furthermore, they can also be, either, a “flat tappet” type, or a “roller type”. Mechanical (Solid) lifters, are as the name implies, solid. There is no internal mechanism, to take up clearance, and in fact, they require clearance to operate properly. A hydraulic lifter, is designed to help with differences in valve train clearance, in order to automatically maintain zero lash.

How Do Hydraulic Valve Lifters Work?

Well, they fill and remove engine oil from the lifter, through a metering orifice and a check valve. In a hydraulic lifter, the seat moves, by means of a hydraulic valve, and oil pressure within the body.

So, when the lifter is filling with oil, it is pumping up. But, when the oil is exiting the lifter, it is bleeding or leaking down.

NOTE, Tappets or cam followers, are just other names, for the same thing.

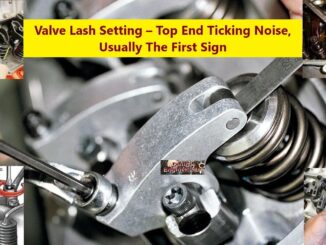

Valve Lash Setting, What Is It?

This describes the amount of clearance, between the rocker arm and the valve stem. This happens when the lifter, is on the base circle of the camshaft. But, mechanical lifters are different. Because, they have a predetermined lash or clearance. When setting the valves on an engine with hydraulic lifters, you are not really setting the lash or clearance.

In reality, you’re actually setting the preload on the lifter, through the pushrod and rocker arm. The traditional adjustment on a hydraulic lifter, is zero lash. Usually, followed by a predetermined amount of turns, on the hold down nut.

Advantages, Of Hydraulic Valve Lifters

So, how is the hydraulic lifter, able to assist with valvetrain slack, while maintaining zero lash? To understand the process, we should look at, its inner workings. When the valve is closed, the plunger spring in the hydraulic lifter, takes up all clearance in the valvetrain.

Oil enters the lifter body, through feed holes and flows inside to the plunger. The oil continues to flow, down through the hole, in the bottom of the plunger. Then, around the check valve and through the holes, in the check valve retainer. In short, to completely fill the cavity below.

Then, the lifter begins to ride up the cam lobe. As, the oil below the plunger, tries to escape, past the check valve. This sudden flow of oil, forces the check valve to seat. Consequently, sealing the hole, at the bottom of the plunger. Now the full load of the valve train, is on the lifters.

It is extremely hard to compress any fluid. So, this makes the lifter now act, almost as if it were, a solid design. There is a predetermined and closely held clearance, between the lifter’s plunger and its body. Consequently, this clearance permits a minute amount of oil, to escape from below, moving past the plunger.

This movement of the plunger, with respect to the lifter body, after the check valve is seated is called, leak down or bleed down. As a result, it consists of the oil, draining out. As the lifter returns to the base circle of the camshaft, oil fills the high pressure cavity. Then, the cycle begins again.

Disadvantages, Of Hydraulic Valve Lifters

Another potential fault of hydraulic lifters, can happen at extremely high engine speeds. Because, valvetrain inertia may open the valves, further than intended. This results in, added valve train clearance and noise.

A hydraulic lifter senses this clearance, causing the plunger to lengthen. And, may actually extend far enough, to prevent the valve from closing. This could result in, valve to piston collision or burnt valves.

Also, a hydraulic valve lifter cannot follow, an aggressive camshaft profile, like a mechanical design. This limits the engine’s power, and operating speed. In addition, a hydraulic lifter requires a certain amount of time, to respond to changes in the engine. In turn, holding back engine power, when compared to a mechanical design.

Aftermarket performance valve lifters are designed, to pump up and bleed down, at a different rate. The disadvantage is, they often sacrifice, quiet operation and longevity to do so.

Conclusion

So, there are times when the hydraulic valve lifter, needs to be adjusted. But, instead of setting valve lash, a hydraulic system needs to have the preload set, since there is no lash. But, this is usually only required, if the cylinder head has been removed.

BY DANNY BENDER