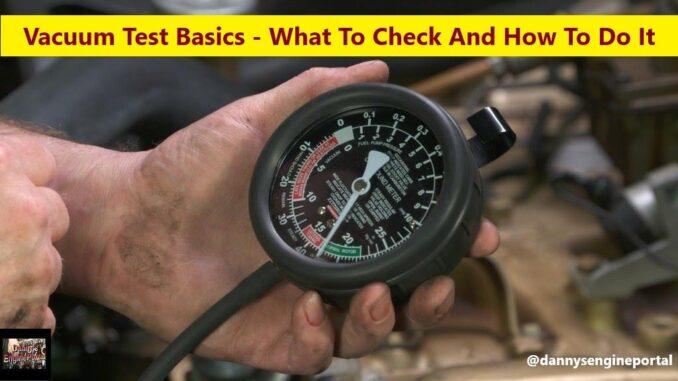

First, doing a vacuum test, can tell you more about your engine, than you think.

And, it is one of the easiest and least expensive ways, to check an engine for serious issues.

So, engine vacuum, is defined as any pressure lower than atmospheric pressure. And, that pressure is produced in each cylinder, during the intake stroke.

So, by doing a vacuum test, in just 3-5 minutes, you can know if an engine is healthy or not.

A vacuum gauge shows the difference between, outside atmospheric pressure. And, the amount of vacuum in the manifold.

So, to check manifold pressure with a vacuum gauge, you need to locate a vacuum port. Usually, in the manifold or throttle body.

Consequently, manufacturer’s install ports on their manifolds, for lots of different reasons. So, you simply need to find one small enough, for the vacuum gauge line to slide onto firmly.

So, there are many factors that can affect the amount of vacuum created:

- Piston rings

- Valves

- Ignition system

- Fuel control system

- Emission controls

Because, each one has a characteristic effect on vacuum, you judge their performance by watching variations from normal. Furthermore, it is important to judge engine performance, by the general location. And, the action of the needle on a vacuum gauge. Rather than, just by the vacuum reading on the gauge.

How To Do A Vacuum Test:

- First, connect the vacuum gauge hose, as close to the intake manifold as possible. And, start the engine.

- Run the engine long enough for it to reach, normal operating temperature.

- Note the location and action, of the vacuum gauge needle.

Most often, even a tiny leak, as small as .020 of an inch can:

- Degrade engine performance

- Compromise driveability

- Turn on your (CEL)

So, a vacuum leak is downstream of the device, that measures the incoming air. That is the Mass Air Flow (MAF) sensor. This means, the engine actually ingests more air, than is getting measured. As a result, the computer gets a wrong low reading.

As a result, that raises the normal 14.7:1 air fuel ratio, causing the engine to run leaner than normal. Finally, the engine computer dithers the mixture ratio, back and forth several times per second in the area of 14.7:1. That’s why, a vacuum test, has many benefits.

How Does This Affect, The Exhaust Mounted Oxygen Sensor (O2)

Well, it will quickly detect the extra air, and in response the computer will richen up the mixture. Because, it’s a self-correcting closed-loop system. Unfortunately, the leak may cause the nearest cylinder, to run leaner than the others. The (ECM) will then richen up the overall mix. All, in an attempt to bring the excess oxygen in the exhaust, back to the appropriate low level.

Consequently, that will force the other cylinders to be too rich, which may cause a whole list of issues:

- Engine misfires

- Fluctuating idle

Furthermore, this might set a (DTC), and turn on the (CEL).

So, today, with all the vacuum hoses running everywhere, there are plenty of places, for leaks to crop up. Furthermore, the ducting that runs between the throttle body and the (MAF) sensor, often 3-inch-diameter rubber, can also degrade.

As a result, a leak in this duct, isn’t technically a vacuum leak, it’s a metered air leak. So, if extra air slips past the throttle body, without being accounted for by the computer. Then, your engine is running lean.

More About, Engine Vacuum Testing

Remember that engine vacuum, is just air pressure, lower than atmospheric pressure. So, the starting point to evaluate engine vacuum, is at the manifold.

Therefore, when you connect a gauge to a port on the intake, you’re measuring manifold vacuum. That’s why, a vacuum test, has many benefits.

Vacuum can also vary, in different areas of the engine:

- Above the throttle valve

- Below the throttle valve

- The intake ports

- The exhaust ports

To clarify, vacuum drawn from an opening, ahead of the throttle is called, ported vacuum. So, throttle opening affects ported vacuum, opposite to the way, it affects manifold vacuum. For example, at closed throttle, manifold vacuum is at its peak. But, there is no significant vacuum, at a port ahead of the throttle plate, when the throttle is closed. Vacuum appears at such a port, only when the throttle opens.

Consequently, many vehicle systems need, a steady supply of low-pressure air, under all engine operating conditions. And, these systems include, power brake boosters, a/c vacuum motors and some emissions controls.

So, ported vacuum, is used to control vehicle systems, connected to engine load. As a result, these include, out of date distributor vacuum advance diaphragms and carburetor assist devices. They also include, many emissions control devices and transmission shift points. So, under some engine load conditions, ported vacuum may equal manifold vacuum. But, it can never exceed it.

In Summary: Vacuum Test

So, a vacuum test, can help you find the source, of your engine mechanical problems. That’s why, the vacuum gauge still remains, a good tool for many shops.

Thank You !!