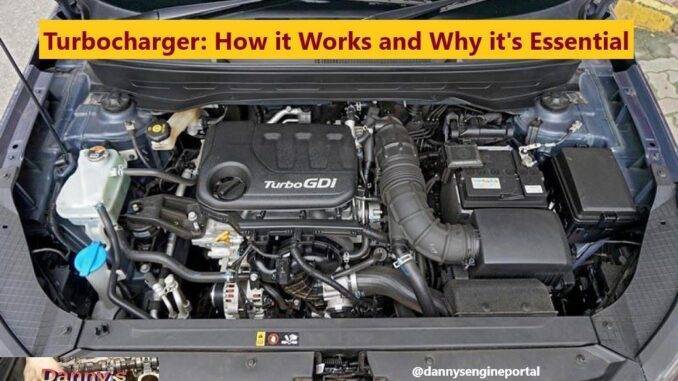

Smaller engines with a turbocharger appeal to consumers, and auto companies. Because, they offer more power, but with the fuel efficiency, of a smaller engine.

Turbochargers made it possible, for the smaller engine, to keep the same speed and performance, as its larger predecessor. Consequently, by making use of exhaust gases.

The additional air produced, by the turbocharger, gets pushed into the cylinder, allowing for more fuel to be burnt. That’s why, a turbocharger, can increase the power of your engine, by up to 35%.

And, that’s what makes a turbocharger, one of the most important accessories, on today’s smaller engines.

So, What Is A Turbocharger And How Does It Work ?

A turbocharger is effectively, two little air fans. They sit on the same metal shaft, so that both spin around together. One of these fans, called the “turbine”, sits in the exhaust stream from the cylinders. As the cylinders blow hot gas past the fan blades, they rotate turning the shaft they’re connected to.

The second fan, is called the “compressor”. Both the turbine and compressor fans, are on the same shaft. It’s mounted inside the air intake. So, as it spins, it draws air in, and forces it into the cylinders. Another important part is the heat exchanger. Consequently, heating and cooling the air, at the proper times.

So, to break it down, this is what happens:

- Cool air enters the engine’s air intake, and heads toward the compressor. The compressor fan, helps to suck air in.

- The compressor squeezes and heats up the incoming air, and blows it out again.

- Hot, compressed air from the compressor, passes through the heat exchanger, which cools it down.

- Cooled, compressed air, enters the cylinder’s air intake. The extra oxygen helps to burn fuel in the cylinder, at a faster rate.

- Since the cylinder burns more fuel, it produces energy quicker, sending more power to the wheels.

- Waste gas from the cylinder, exits through the exhaust outlet.

- The hot exhaust gases, blowing past the turbine fan, make it rotate at a high speed.

- The turbine is mounted on the same shaft as the compressor. So, as the turbine spins, the compressor spins as well.

- The exhaust gas leaves the engine, wasting less energy than it would otherwise.

So, turbochargers give a engine more power. But, that extra power is not coming directly from the waste exhaust gas. And, that sometimes confuses people.

FACT: A turbocharger, reuses some of the energy in the exhaust, to drive the compressor. As a result, allowing the engine to burn more fuel. This extra fuel, is where the engines extra power comes from. All the exhaust gas is doing, is powering the turbocharger. The turbocharger, isn’t connected to the car’s crankshaft or wheels. So, it’s not directly adding to the car’s driving power.

Do Turbochargers Save Fuel ?

The basic advantage of using a turbocharger is, that you get more power output, from the same size of engine. However, that means, you have to put more energy in as well. So, you must burn, correspondingly more fuel. In theory, that means an engine with a turbocharger, is no more fuel efficient than one without.

An engine with a turbocharger, is smaller and lighter, than an engine producing the same power, without a turbocharger. The result is, that a turbocharger can give better fuel economy in that respect. As a result, manufacturers can often get away with, fitting a much smaller engine to the same vehicle.

Such as, a turbocharged V6 instead of a V8, or a turbocharged four-cylinder engine, instead of a V6.

And, that’s where turbocharged engines, get their advantage. Working well, they might save up to 10 percent of your fuel. Since they burn fuel with more oxygen, they tend to burn it, more thoroughly and cleanly. As a result, producing less air pollution.

Failure, Warning Signs

So, there are a variety of symptoms, that are commonly associated with, turbocharger failures. Therefore, by carefully analyzing the performance of the vehicle, helps to spot irregularities and diagnose turbocharger failures.

Some of these signs include:

Loss Of Power And Acceleration

One of the most significant symptoms, of a failing turbocharger is, lack of overall power. Your vehicle may not accelerate as quickly as expected, or generate the expected amount of power while running. So, if you notice that your vehicle is sluggish, it could be a sign of a failing turbocharger.

A Loud Siren, Shrieking Or Whining Noise

Turbocharged engines can make good noises, such as spooling or a blow off valve noise. But, there are also some bad noises as well. Sounds like that of, a police siren or dentist’s drill. Also, if the noise keeps getting louder, it could be a sign of a faulty turbo. It usually is the result of, a loose pipe or malfunctioning blades in the turbo.

Irregular Or Excessive Exhaust Smoke

A malfunctioning turbo, can cause more exhaust smoke to be produced than normal. Most of the time, there is oil leaking into the exhaust. When this leaked oil burns, it will result in a characteristic, blue or grey smoke. This smoke is more visible, when the turbo is running. Hence, if you notice excessive smoke, when revving the engine, chances are your turbo is faulty.

Increased Oil Consumption

When a vehicle uses more oil than normal, this is a big warning sign, that something isn’t right. If the turbo is leaking oil, you can see it, inside the turbine. Increased oil use is common, for a gradual turbo failure. But, should still be fixed as soon as possible.

Check Engine Light (CEL) And Trouble Codes

Most of today’s cars have computer systems, that are capable of detecting turbo faults. Consequently, triggering the check engine light (CEL). However, the check engine light (CEL) cover various other engine issues. So, it’s advisable to do some further diagnostic tests, to find out what exactly is ailing your engine.

But, before you point your finger at your turbocharger, make sure that the car, has good all round health. For example, a faulty (EGR), can cause excessive exhaust smoke and poor acceleration, if blocked. Likewise, when you have a blocked (DPF), it will often cause the car to go, into limp mode-reduced power. Also, while going through regeneration of the (DPF), there could be excessive smoke.

- P2262 OBD-II Trouble Code

P2262 is a diagnostic trouble code (DTC) for (Turbo Boost Pressure, Not Detected-Mechanical). Basically, this code indicates that the, turbo turbocharger control is damaged, and requires immediate attention. Vehicles that face this problem, will experience a loss of engine power. The engine will have low or no turbo boost. And, will lack power on acceleration or under load. In the worst cases, they can face costly internal engine damage as well.

Be aware that the P2262 code can cause an engine, to feel like it has more power than usual. This isn’t a good thing because, the over boost, can cause the engine to blow head gaskets.

If you want to fix the P2262 code, there may be a need for you to replace the:

- Turbocharger control actuator assembly.

- The turbocharger assembly.

- Repair/replace the wire harness.

- The connection to the control actuator.

Other Possible Codes:

- P0234 Code.

- PO299 Code.

Boost Gauge, Warning Signs

Hopefully your car comes with, a boost gauge or you have installed an aftermarket one. If so you have an excellent way, of finding out how well your turbocharger is functioning.

A drop in the boost level, is a sign that the performance of your turbocharger is compromised. Normal boost, should be anywhere from, (9 psi to 14 psi) for most normal turbo engines.

Turbocharger, Failure Causes:

Cracked Or Leaking Seals

A turbocharger forces air, back into the cylinders. Cracked or broken seals, can cause air leaks. This often means the turbo will become overworked, in order to maintain the applied boost. This is a fairly common problem, that leads to a faulty turbocharger.

Normal Wear And Tear

Even with proper maintenance and care, a turbocharger endures wear and tear over time.

So, the lifespan of a turbo dramatically depends on:

- Driving habits of the car’s owner.

- The quality of the turbo parts.

- Also, make and model of the vehicle.

That’s why, the typical turbocharger, has a lifespan of about 120,000 kilometers (~75000 miles). However, car owners can check the manufacturer’s information. Then, verify how long their turbo may last, before it becomes faulty.

Carbon Deposits

Failing to change the oil or the oil filter regularly, can cause the buildup of carbon deposits. Fresh oil benefits the entire motor, including the turbo. Remember, even the smallest amount of particles and contaminants, can cause serious problems.

Buildup Of Debris

Small particles or objects, such as rocks or dirt can enter the turbocharger, through the turbine or compressor inlet. Even more, if the air filter fails to catch debris, while the car is in motion. If this occurs, the buildup of debris can cause compressor wheel abrasion, or damage to the turbine blades. Any of this, will diminish the performance of the turbo.

Diagnosing, Turbocharger Issues

Turbochargers add another layer of mechanical complexity, to an ordinary engine. Consequently, there are quite a few more things to go wrong. That can make maintenance of turbos, more expensive. By definition, turbocharging, is all about getting more power, from the same basic engine design. Many of the engine components have to suffer higher pressures and temperatures, which can make parts fail sooner. That’s why, turbocharged engines, don’t last as long.

The easiest way to diagnose a weak turbo, is to observe the vacuum/boost gauge or boost indicator light. If it doesn’t show normal boost pressure at full throttle (usually 9 to 14 PSI), better get it checked.

Excessive back pressure (often due to a clogged catalytic converter), can also prevent the turbo from developing, normal boost pressure.

If you’re mechanically inclined and aren’t afraid of looking under the hood, you can check for a range of faults. Start by inspecting the turbocharger. Essentially, you are looking for signs of oil, excessive movement, impact damage. And, contact, between the compressor wheel and housing. Before you start the process, we recommend checking the air filter, exhaust system and fuel system. Most of these can cause, similar symptoms to turbo failure.

Once you’ve done that, you’ll need to remove the air filter to gain access to the turbo.

First, examine the exterior, checking for any signs of oil or loose connections. Then, check the compressor wheel. It should be clean, without any dings, chips, or signs corrosive pitting. Look out for evidence of excessive movement, ensuring that the wheel can’t touch the housing. Also, check to see whether the turbocharger, is able to rotate freely.

If you are feeling particularly determined, you can also check, the exhaust side of the turbo. First, remove the exhaust pipe all the way to the turbo, so you can see the turbine wheel. This should look clean, with no carbon build up, scale or oil along the surface. The blades should be free from cracks, wear and damage. Finally, you can check the turbo housing at the exhaust end, for any cracks or leaks.

Conclusion

To work effectively, a turbo needs a constant flow of clean oil, to keep your turbo in top condition. So, you need to ensure that you change the oil and oil filter regularly. This helps to prevent, the buildup of carbon deposits and contaminants, that can cause abrasive damage. Fully synthetic oils, produce the least amount of carbon.

Sometimes, foreign objects, like broken engine components, dust particles, small stones, dirt and leaves, can enter your turbocharger. These can then cause impact damage and abrasion, to the compressor wheels and turbine blades. As a result, reducing the efficiency of the turbo. To prevent this from happening, you need to ensure that your air filter and oil, is replaced regularly. Along, with checking your turbo for, loose connections or debris.

BY DANNY BENDER