Without having the proper torque specification, assembling an engine, is just asking for failure.

This is especially true, on today’s lightweight engines, that use mostly aluminum castings.

So, having the proper torque specification, is crucial information, whenever you make repairs. Consequently, I know many people believe, some places are more important to torque than others, But, any time a manufacturer recommends one, they do it for a reason.

And, it’s not enough to just know the torque specification, you also need to know the correct sequence. Because, most often you are trying to seal oil, coolant, vacuum and combustion.

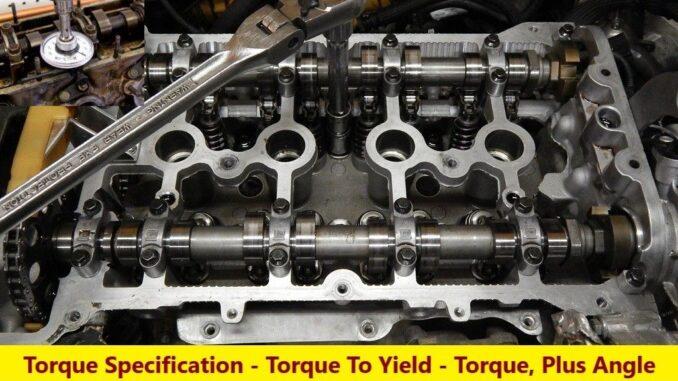

Torque Specification – Bolt Stretch And Lubricant

Most people do not realize that, a bolt or a stud, acts like a big spring to hold parts together. So, it needs to be stretched a certain amount, in order to do its job. Even though there are tools to measure bolt stretch, most people do not own them.

But, almost anyone who fixes mechanical problems, will have a torque wrench. Most engine torque specification require 30w engine oil, to get the correct stretch on the bolt. However, using the wrong lubricant, will affect the clamping load.

Also, some specialty fasteners, require a specific lubricant. As a result, it is important to know which lube, and if any is required.

So, a torque wrench, really only senses friction. For example, take a bolt with a torque specification of 50 ft. lb. Tighten it with no lubrication at all and mark it, so that you know where it stopped turning. Now, loosen the bolt and apply some engine oil to the threads and under the head of the bolt.

Subsequently, when you torque it again, it will most certainly turn, considerably further. In other words, it has stretched more. This is why it is so important to know, what if any lubricant, the manufacturer specifies for each fastener.

It is also important, to pull on the torque wrench, slowly and evenly, without any type of jerking motions.

Torque Plus Angle, Torque Specification Method

So, this method of tightening fasteners in engines is relatively new. And, the reason for it, is to get a more consistent stretch in the bolts. Since a torque wrench senses friction, there are a lot of variables, that can affect proper tightening.

Start by using the torque wrench, for a small initial torque, to seat the bolt. Next, turn the bolt a certain number of degrees of rotation. Now, the manufacturer can be pretty sure, that the correct stretch, is apply to the bolt. An example would be, to tighten the bolt to 20 ft. lb. and then, turn it an additional 90 degrees.

There are torque angle tools available, that will work with a standard ratchet. Consequently, these tools enable you to accurately measure, the number of degrees you are turning the bolt. Fel-Pro makes a very inexpensive plastic version, that is great for the home mechanic.

What About, Torque Specification To Yield (TTY) Bolts

Torque to yield (TTY) bolts are stretched, to the point that they are, just about to “yield”. At that point they lose their springiness. These types of fasteners, can only be used once, and then must be replaced.

Torque Plus Angle, Is Not The Same As Torque To Yield (TTY)

So, a lot of people, including professional technicians, may not understand. Just because a bolt uses the “torque plus angle” method of tightening. Does not necessarily mean its a Torque To Yield (TTY) bolt.

If you’re about to get a new Honda, whether it’s one of their 7 seater cars or a 2 seater. Then, it’s important for you to know about the following, if you ever want to tinker with the torque. Consequently, Honda has used the “torque plus angle” method of tightening head bolts, for many years. I do not think that any of their head bolts require replacing. So, they are not, (TTY) bolts.

In Summary: Torque Specification

So, not all torque wrenches, are universally adaptable to all jobs. Furthermore, it’s important to choose one that features, your torque value requirement, in the middle of its range. For instance, if you need to tighten a main bearing bolt to 100 ft.-lbs. Then, don’t use a torque wrench model, that has an upper range limit, of 100 ft.-lbs. Helpful torque specification tips.

Instead, use one that has a range of, say, 25 to 250 ft.-lbs. In other words, if tightening a fastener to 50 ft.-lbs. Then, use a torque wrench that has an upper limit of, about 100 ft.-lbs. and so on. Finally, you may need torque wrenches with different ranges, depending on the type of work your doing.

Thank You !!