The cylinder bore deglazing process is basically, removing the glaze from your engines cylinder walls.

Because, having the proper finish, is extremely important in helping with, proper piston ring lubrication.

So, without proper lubrication, heat and friction can cause, excessive engine wear. In contrast, too much lubrication, will cause excessive cylinder leakage and oil burning.

Cylinder bore deglazing is not that hard to do, if you follows the proper instructions.

So, to keep your engine running at peak performance, the cylinder bores need the proper oil retaining surface finish. But, at some point the reciprocating movement of the pistons, can glaze the cylinder walls.

As a result, the surface finish becomes too smooth, and will not hold the oil as effectively. Even more, this cylinder wall glaze affects more than just lubrication.

This Glaze Also Affects:

- The performance of your piston rings

- Other engine components, that seal the combustion chamber

- Proper heat transfer

- The control of oil consumption

The Purpose Of Cylinder Bore Deglazing

So, cylinder bore deglazing, is the process of conditioning the surface finish, of the cylinder walls. Consequently, allowing for the proper lubrication of the piston rings, during engine operation. In addition, to promoting proper lubrication, cylinder bore deglazing also supports, piston ring seating and sealing.

So, you need a very thin layer of oil, between the edge of the piston rings, and cylinder wall. If there was no oil to lubricate the constant contact with the cylinder wall, there would be too much friction. As a result, both the rings, and cylinder would wear out quickly.

Using A Ball Hone In A Reversible Drill

One of the advantages of using a ball hone in a drill, is that you can run the drill backwards. So, if you deglaze in the opposite direction (counterclockwise), it will do a nice job of deburring the surface.

Proper Crosshatch Angles

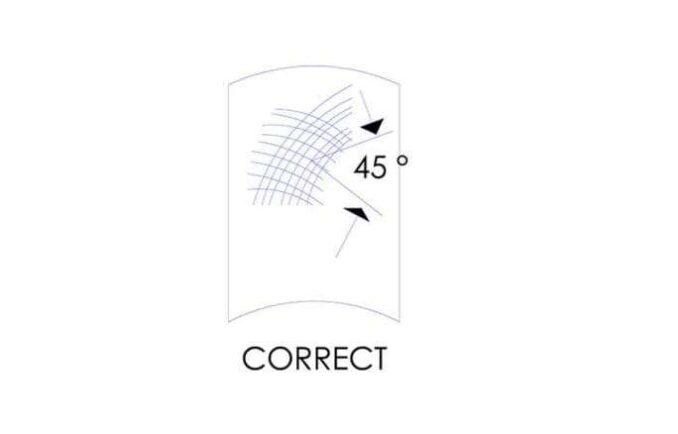

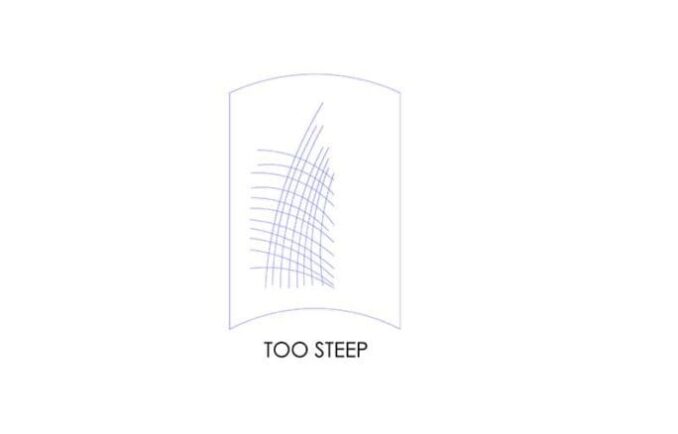

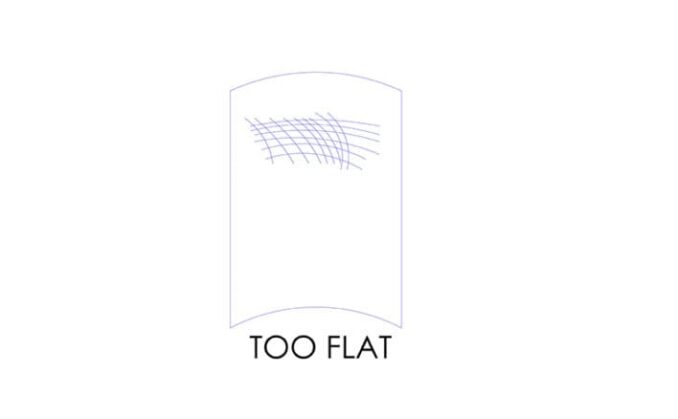

The Correct Angle For Crosshatch Lines To Intersect, Is Approximately 45 Degrees:

- So, if the crosshatch angle is too steep, the rings can pump oil, or experience excessive rotation. And, will accelerate wear in the rings, and piston lands.

- In contrast, if the crosshatch angle is too shallow. It can have a ratcheting effect, as the rings pass over the valleys. As a result, preventing the piston rings from receiving proper lubrication.

Cylinder Bore Deglazing Methods

So, there are two methods used to deglaze cylinder walls, either rigid stones or a flexible ball hone. However, if there is no wear in the cylinder, use the ball hone.

Correct cylinder finishes can be achieved with either system, if used correctly. Because, there are different methods, there are also different instructions as well. Above all, follow the instructions for the cylinder bore deglazing equipment you are using.

Cylinder Roughness And Angle

Substantial controversy exists on the correct cylinder roughness, for proper seating of piston rings. Mainly, because of the different finishes required, when using a chrome, moly, or plain cast iron ring. So, it is important to follow what the ring manufacturer, says for proper cylinder finish. Because, different rings materials, require different finishes.

Most manufacturers say the angle of the scratches in the crosshatch pattern, should be about 45° to each other. Or, equal to about 22° to 32° of the horizontal deck surface. The crosshatch angle should be the same, throughout the length of the cylinder, and not flatten out at either end.

Cylinder Block Cleaning

The single most critical factor of any cylinder refinishing job, is the cleaning of that cylinder, after the deglazing operation. Because, no engine component will tolerate dirt! Especially, engine bearings. So, cylinder bore deglazing, leaves two types of “dirt” on the cylinder walls, honing stone residue and cast iron dust.

Proper cylinder cleaning consists of, a complete washing of the block. Always, with hot, soapy water taking care to clean the surface, under the cylinder facing the crankcase. Finally, a rinsing with hot water, drying and light coating of oil to prevent rust.

Conclusion

So, for detailed cylinder bore deglazing questions, it is wise to contact the manufacturer of your specific equipment. Because, they are experts in metal finishing and of course, completely understand their own equipment.

BY DANNY BENDER