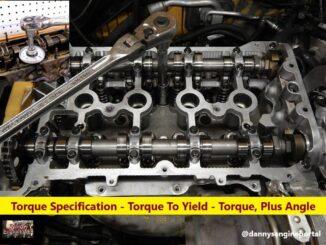

Torque to yield bolts, are exactly what they sound like. So, when tightened, they stretch to the point of yield.

Many vehicle manufacturers use torque to yield bolts. Especially, on engines with aluminum heads, and or in conjunction with (MLS) head gaskets.

Because, they provide more consistent clamping loads, across the entire head-to-block mating surface.

So, torque to yield bolts, are nothing new, but are more and more common on today’s vehicles.

Quite often a shop manual indicates, that a bolt is to be discarded, and new ones used. That means they are almost always, talking about torque to yield bolts. Buying new bolts, may seem expensive. After all, the old bolts still look good, but looks can be deceiving. Reusing the old bolts, can cause expensive engine failures. So, only new bolts can provide the even clamping force, needed on today’s engines.

So, Why Do We Need These, Torque To Yield Bolts, Now !!

We didn’t need them, in the 1960′s or 70′s! I guess the simple answer is, engine materials are different. Aluminum cylinder heads, expand at a different rate, than cast iron blocks. So, as an engine warms up, bolted together parts, have to move against each other, or slide on their gaskets.

As a result, the elastic properties of the torque to yield bolts, allow movement between parts. While, still maintaining even clamping loads and sealing.

Engine parts are also, lighter than they were a few decades ago. Heavy cast iron parts, could withstand some variations in torque, without failures. So, thin wall castings and aluminum alloys used today, require extremely accurate torque or warping and leaks occur.

Common Installation Instructions

So, you will use an actual torque figure, in the first step of the tightening process. Because, this provides a uniform baseline, from which the true load, is then applied. This is commonly referred to as, a preload or snug torque.

A typical tightening specification for, torque to yield bolts, would look as follows:

- First, Uniformly tighten in sequence, in several passes to ? Foot Lbs.

- Next, tighten in sequence ? °

- Next, tighten in sequence a further ? °

This procedure ensures that friction, does not cause, uneven bolt loading.

Bolts are elastic by nature. Meaning that, within their elastic range they’ll stretch, as the load on the bolt increases. Typical bolts can be an issue, when you use them on aluminum heads. And, with a gasket that doesn’t relax, like an (MLS) gasket. The expansion rate of aluminum heads, will stretch typical bolts, past their yield point and can snap them. Hence, the need for, torque to yield bolts. Also, there is a torque, plus angle application.

Unfortunately, using a larger diameter bolt, is not the answer. Because, the larger a bolt is, the less it will stretch. Remember, bolt stretch, is how we get maximum clamping load.

Starting the bolt turning, takes more force than keeping it turning. The tighter the bolt, the more stiction, can affect torque readings. Lubrication helps the threads slide easier. But, one lubricant differs from another, in their lubricating qualities. So, manufacturers will specify what type of lubricant, if any to use on a bolt when torqueing it. And, using the wrong lubricant, will affect the clamping load.

Torque To Yield Bolts – Important Tip !

Before removing torque to yield bolts, allow the engine to fully cool. Removing the bolts while the engine is hot, can cause cylinder head warpage. Above all, always remove them in the reverse order, of the torque sequence. Because, this will help reduce cylinder head warpage.

Conclusion

So, the expansion rate of aluminum heads, will stretch typical bolts, past their yield point. And, can causing them to snap. Also, newer engines, require high clamping forces, (due to increased combustion pressure).

BY DANNY BENDER